sheet metal design checklist Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. Starting with the signature fully boxed frame, Ford engineers increased the use of high-strength 70,000-psi steel – from 23 percent to 77 percent of the frame – to improve stiffness and durability while reducing weight. The new frame is .

0 · standard sheet metal parts

1 · standard sheet metal design

2 · sheet metal parts design

3 · sheet metal installation restrictions

4 · sheet metal design guide

5 · sheet metal design dimensions

6 · how to design sheet metal parts

7 · how to design sheet metal

Welding, Brazing, Soldering and Metalworking - distributor box? - Hi. I just received as a gift a 250 amp stick welder that I would very much like to practice on.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Sheet metal bending is a forming operation where sheets are deformed plastically to .It helps designers in sheet metal product design because designers design parts .

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.Sheet metal DFM - design guidelines for formed and punched parts. A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Whether you’re a seasoned .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Checklist – Sheet Metal. . The drawing covered by this checklist is a design record for engineering used to communicate the requirements of the part to suppliers for their process control and to your company incoming inspection processes. Common Drawing Format Requirements. Item:Include common sheet metal specific information. . If you want a starting point for this checklist in pdf, google sheets, . Despite the best intentions of design engineers and drafters designing sheet metal parts, items will be overlooked. .Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000.

Sheetmetal Design Guidelines - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document provides guidelines for designing sheet metal parts, including: - Bends should face the same direction if on the same plane to avoid part flipping. Large parts with small flanges should be avoided.

standard sheet metal parts

Hems are an essential element in sheet metal design, enhancing the strength of edges and eliminating sharpness, though they contribute additional weight to the part. Hemming is the process of folding a piece of sheet metal over itself; this can improve aesthetics by hiding edges or burrs, and provide added strength and reinforcement. . Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements Dimensions: Length, width, and height. Material: Type of sheet metal (e.g., aluminum, stainless steel, galvanized steel). Thickness: Gauge of the sheet metal. Functionality: Purpose of the .

3d printer head for cnc machine

If you are planning to become a sheet metal designer or product design, then this is the right course for you. In this course, you will learn about design considerations; a designer needs to keep in mind while designing a product. I have not discussed any sheet metal operation here. I am discussing the consideration which a designer should use .The Design Checklist for Automotive Sheet Metal Engineer is used during the design phase of automotive sheet metal components. This checklist serves as a guide for engineers to ensure that all necessary design considerations are taken into account. It helps in identifying potential issues and ensuring that the design meets the required . How to design bend reliefs for sheet metal with CAD software. There are two common ways to add bend relief to your design. One way is to do it manually. . Before you upload your design files, be sure to go through our pre-flight checklist: File is in a format that we accept (2D: .dxf, .dwg, .ai, .eps; 3D: .step or .stp) .

enclosure-design-review-checklist - Free download as PDF File (.pdf), Text File (.txt) or read online for free. During the design phase, sheet metal design guidelines focus on the following 5 parameters. Material Selection. During the process, the material characteristics play an important role in determining the suitable process for the specific material. Consider the example of Aluminum and Steel to understand this better. Naturally, cutting Aluminum .Review and understand the project specifications Take the time to thoroughly review and understand the project specifications. This task is crucial for ensuring that the fabrication process meets the required standards and the final product meets the client's expectations. Consider the materials, dimensions, design requirements, and any specific quality control measures .

standard sheet metal design

Sheet Metal Design Guide. Whether you design custom enclosures or parts from scratch, or use our time-saving templated tools (Protocase Designer, Template Generator and Cutout Library) to create what you need, knowing the basics of sheet metal design will make your work easier.Our 31-page digital guide provides information and guidance on all of the basic concepts of sheet . When preparing a design for laser cutting and bending with SendCutSend, there are a lot of factors to consider – bend deduction, material stiffness, and bend reliefs to name a few! In this article, we’ll show you how to preflight the flat, 2D vector file of your design for bending services using QCAD.. QCAD is a free, open source 2D program we frequently recommend for .

The first common issue when designing sheet metal using Solidworks is not using the sheet metal tool. While designing 3D parts in Solidworks can be a straightforward process, designing for sheet metal is . Utilizing feature-based modeling also aids in maintaining precision, as it creates a history of operations that can be edited, ensuring measurements are consistent and traceable.. CAD also simplifies the .

Sheet Bending Machine Maintenance Checklist: A Comprehensive Guide . 3 Sorts of Sheet Metal Processing Equipment Details 2024/01/30. . 2024/05/11. Innovations in Steel Strip Slitting Machine Design and Technology 2024/05/11. Improving Accuracy in Metal Fabrication with Laser Metal Shear Machines

Sheet metal fits all “green” building materials measures, especially recycled content – Recycled content: steel = 25%; roofing copper = >75%; – Energy efficiency per Florida Solar Research = light-colored metal roofs VERY energy efficient Soldered sheet metal joints are “sustainable” and do not require continuous maintenance—unlike9. If 7 is yes, is the product symmetrical in design? 19. Are Pro E models available? 10. Are maintenance costs built into the price? 20. What level of tooling supports the business? 11. If there is existing product running, is it running under deviation? 21. Mold Design Checklist Can the part date code (clock code), if applicable, be

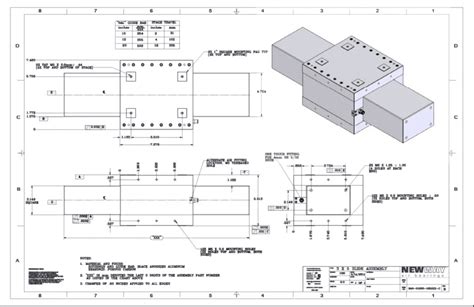

The basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. 1. Wall thickness. Sheet metal parts are usually fabricated from a single sheet of .I design lots of sheet metal components, often welded multi body structures with many self-clinching fasteners. All of our sheet metal shops require both an accurate 3D model and fully dimensioned and toleranced drawing.

The document is a checklist for reviewing die design. It contains over 95 questions across 5 sections checking various aspects of the die design such as the part and process details, die layout, general die design, lower die design, and upper die design. The questions cover issues like material specifications, tonnage calculations, dimensions, components, process flow, and .

sheet metal parts design

The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization. Panel joinery guidelines recommend spot welds be loaded in shear and have a total material stack of 4-4.5mm. The BIW manufacturing process involves pressing panels, . Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines and structures from various raw materials. This guide will help you to understand sheet metal product design tips and fabrication techniques. Metal. Metalworking

For sheet metal design, many professionals recommend using SolidWorks software. SolidWorks has powerful sheet metal design tools that allow for the rapid, accurate creation, modification, and analysis of various sheet metal parts and assemblies. Other popular software packages include Autodesk Inventor and Fusion 360, CATIA, and Siemens NX.Here you'll find our metal stamping for beginners checklist of what you'll need & all you'll need to know! . Practice Sheet Metal. . Our Stamping on Metal Starter Kit has everything you need with the exception of the hammer, design stamps and pliers. If you have a household hammer, this could be the choice for you. Optional: Design Stamps .

Creating optimal enclosure designs that reflect your requirements and intent can be challenging at the best of times, let alone when it’s unchartered territory. That’s why, over the past decade, we’ve created resource material to share our knowledge of sheet metal and enclosures, including this sheet metal design guide.

3d printed electric skateboard enclosure

3d printing and cnc machining

GEM BOX. Description: This is a metal box 2 inches wide, 3 inches high, and 2 1/2 inches deep, with or without plaster" ears. "Buying information: This is the standard box for switches and receptacles. A single gem box (or gang box) has room for one receptacle or switch.

sheet metal design checklist|how to design sheet metal parts