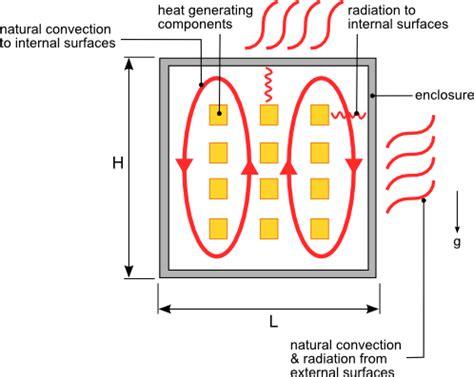

electrical enclosures heat dissipation Accurately calculating the temperature rise of each component housed inside the enclosure is a complicated task that is best accomplished using computational fluid dynamics and heat transfer software.

Order parts and accessories for all types of CNC machines. Cutting tools, workholders, toolholders, measurement and calibration devices, and more.

0 · heat dissipation in sealed enclosures

1 · heat dissipation in enclosure

2 · heat dissipation formula in watts

3 · heat dissipation calculation for panel

4 · enclosure temperature rise calculator

5 · enclosure temperature

6 · electrical enclosure heat load calculation

7 · circuit breaker heat dissipation

Precision CNC Machining Parts Service & Custom CNC Machined Parts Manufacturer. Bergek CNC is good at making prototypes, small-batch, or mass-production customized CNC machined parts. Come to get instant quotes on metal and plastic machined parts.

Calculating an electrical enclosure's heat dissipation rate is the first step to prolonging the life of your electrical components. Use the following information to calculate input power and temperature rise and determine the heat dissipation .

Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power .Dealing with heat losses in enclosures depends on whether the enclosure is equipped with cooling accessories, like filter fans and cooling units, and whether the enclosure is supposed .heat dissipated in the enclosure (in watts) by the enclosure surface area (in square feet). Locate on the graph the appropriate input power on the horizontal axis and draw a line vertically until it intersects the temperature rise curve. . In this article, we’ll discuss the basics of calculating temperature rise inside enclosures, and we’ll also quickly review some options for dissipating the heat produced inside an enclosure — from ventilation to heat sinks to .

Accurately calculating the temperature rise of each component housed inside the enclosure is a complicated task that is best accomplished using computational fluid dynamics and heat transfer software.

Evaluation of the environmental conditions of an electrical enclosure to calculate the thermal dissipation. In order to obtain the thermal balance of an electrical cabinet, the “design conditions” must be defined, i.e. . You can do this by taking the amount of heat dissolved within the enclosure expressed in watts and dividing it by the square feet of the enclosure’s surface area. Once you have the electrical input power, you can use the graph .

substitute for electrical junction box

heat dissipation in sealed enclosures

Enclosure designs that do not allow adequate heat dissipation and air flow, resulting in very high internal temperatures. Enclosure designs that lead to hot spots because of lack of air .The accumulation of heat in an enclosure is potentially damaging to electrical and electronic devices. Overheating can shorten the life expectancy of costly electrical components or lead to catastrophic failure.Calculating an electrical enclosure's heat dissipation rate is the first step to prolonging the life of your electrical components. Use the following information to calculate input power and temperature rise and determine the heat dissipation rate.Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power generated inside the unit, assume 10% of the energy is dissipated as heat.

Dealing with heat losses in enclosures depends on whether the enclosure is equipped with cooling accessories, like filter fans and cooling units, and whether the enclosure is supposed to be “air tight”. For an enclosure that has cooling accessories installed, heat losses can be dissipated through active heat dissipation. If an enclosure has .heat dissipated in the enclosure (in watts) by the enclosure surface area (in square feet). Locate on the graph the appropriate input power on the horizontal axis and draw a line vertically until it intersects the temperature rise curve. Read horizontally to determine the enclosure temperature rise; Example: What is the temperature rise that can be

In this article, we’ll discuss the basics of calculating temperature rise inside enclosures, and we’ll also quickly review some options for dissipating the heat produced inside an enclosure — from ventilation to heat sinks to internal air conditioners.Accurately calculating the temperature rise of each component housed inside the enclosure is a complicated task that is best accomplished using computational fluid dynamics and heat transfer software.

Evaluation of the environmental conditions of an electrical enclosure to calculate the thermal dissipation. In order to obtain the thermal balance of an electrical cabinet, the “design conditions” must be defined, i.e. the desired temperature inside the cabinet and the most critical one in the installation environment. You can do this by taking the amount of heat dissolved within the enclosure expressed in watts and dividing it by the square feet of the enclosure’s surface area. Once you have the electrical input power, you can use the graph underneath to find the approximate temperature rise.

Enclosure designs that do not allow adequate heat dissipation and air flow, resulting in very high internal temperatures. Enclosure designs that lead to hot spots because of lack of air circulation in particular areas of the enclosure.The accumulation of heat in an enclosure is potentially damaging to electrical and electronic devices. Overheating can shorten the life expectancy of costly electrical components or lead to catastrophic failure.Calculating an electrical enclosure's heat dissipation rate is the first step to prolonging the life of your electrical components. Use the following information to calculate input power and temperature rise and determine the heat dissipation rate.

Determine the heat generated inside the enclosure. Approximations may be necessary. For example, if you know the power generated inside the unit, assume 10% of the energy is dissipated as heat.Dealing with heat losses in enclosures depends on whether the enclosure is equipped with cooling accessories, like filter fans and cooling units, and whether the enclosure is supposed to be “air tight”. For an enclosure that has cooling accessories installed, heat losses can be dissipated through active heat dissipation. If an enclosure has .heat dissipated in the enclosure (in watts) by the enclosure surface area (in square feet). Locate on the graph the appropriate input power on the horizontal axis and draw a line vertically until it intersects the temperature rise curve. Read horizontally to determine the enclosure temperature rise; Example: What is the temperature rise that can be In this article, we’ll discuss the basics of calculating temperature rise inside enclosures, and we’ll also quickly review some options for dissipating the heat produced inside an enclosure — from ventilation to heat sinks to internal air conditioners.

Accurately calculating the temperature rise of each component housed inside the enclosure is a complicated task that is best accomplished using computational fluid dynamics and heat transfer software. Evaluation of the environmental conditions of an electrical enclosure to calculate the thermal dissipation. In order to obtain the thermal balance of an electrical cabinet, the “design conditions” must be defined, i.e. the desired temperature inside the cabinet and the most critical one in the installation environment. You can do this by taking the amount of heat dissolved within the enclosure expressed in watts and dividing it by the square feet of the enclosure’s surface area. Once you have the electrical input power, you can use the graph underneath to find the approximate temperature rise.

style selections 2-pack 6.75-in steel window box brackets

heat dissipation in enclosure

stud type plastic junction box

heat dissipation formula in watts

Yizhong Hardware offers one shop for all your production metal parts. We provide CNC machined parts, plastic products and related services. Highly skilled people are at the heart of Yizhong .

electrical enclosures heat dissipation|enclosure temperature