cnc machine collet Southwick & Meister is a leading manufacturer of CNC collets, bushings, cutting tools, and more for various applications. Explore their catalog of standard, semi-standard, and specialty products in different bore sizes and learn about their .

For electric guitars, you should always use an active DI box. The golden rule of DI boxes is that if you have a passive source, you should use an active DI box. On the other hand, active sources benefit from passive DI boxes.

0 · what is a collet chuck

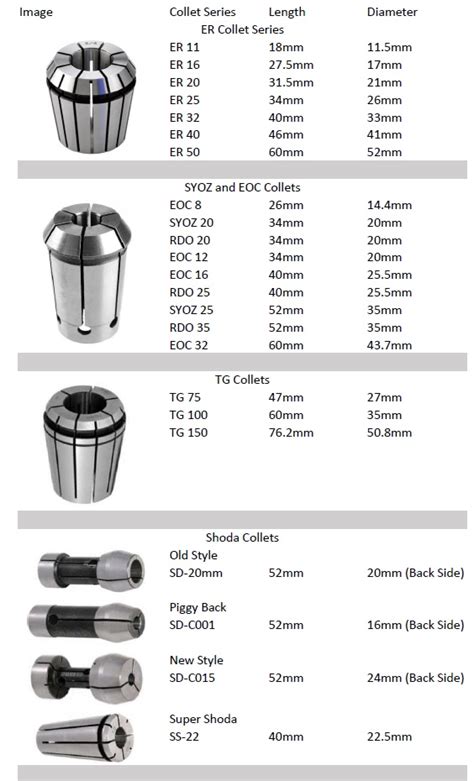

1 · types of collets chart

2 · sealed collet vs non

3 · how to determine collet size

4 · collet identification chart

5 · collet dimension chart

6 · collet chuck for cnc lathe

7 · 5c collet size chart

Get the best deals on Stainless Steel Cabinets when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

Learn about different types of collets used in CNC machining, such as workholding and toolholding collets, and how they work. Find out the features, benefits, and applications of each collet type and how to choose the right one . A CNC collet is a clamping device used widely in machining operations to hold onto a workpiece or cutting tool securely. It fits inside a spindle, chuck, or holder of a machine .Learn about CNC machine collets, cylindrical devices that hold and secure cutting tools in place. Find out how to select, maintain, and troubleshoot collets for optimal machining performance. By understanding the different types of collets available and their specific applications, as well as the properties of various collet materials and coatings, you can make informed decisions when selecting the right collet for .

A collet is a cylindrical toolholder that grips cutting tools or workpieces with high precision. Essential in CNC machines, collets achieve tight tolerances, reduce runout, minimize vibration, and improve machining accuracy.

Southwick & Meister is a leading manufacturer of CNC collets, bushings, cutting tools, and more for various applications. Explore their catalog of standard, semi-standard, and specialty products in different bore sizes and learn about their .Powerful 4˚ taper collets provide improved performance holding tool shanks from 3/32″ to 1/4″ (3mm-6mm). Perform fast slim fit tool changes using just the T-wrench. Why SlimFIT outperforms ER Collet Systems.

ER collets are a type of tool holding device commonly used in CNC machines. They are designed to securely affix cutting tools like end mills, drills, reamers, etc in a CNC machine's spindle. ER . CNC collets are an essential component in machining, responsible for holding the tool in place and ensuring precision and accuracy in the cutting process. There are several types of CNC. What are Collets? Collets are the critical connection between the cutting tool and the tool holder (also called a collet chuck). Most collets are round, cone-shaped, and slotted. Collets encircle the cutting tool shank to evenly distribute holding power around its center bore. To choose the right collet, consider the shank size of your tools, the required precision, the type of material to be machined, and your CNC machine’s specifications. It’s important to select a collet that matches your tool’s diameter and offers the appropriate clamping force and accuracy.

what is a collet chuck

A CNC collet is a clamping device used widely in machining operations to hold onto a workpiece or cutting tool securely. It fits inside a spindle, chuck, or holder of a machine tool, providing a precise and tight grip that prevents the object from moving during the machining process.CNC machine collets are precision-machined cylindrical devices used to hold and secure cutting tools in place within a CNC machine. They provide the necessary grip to prevent tool slippage and ensure accurate machining operations. By understanding the different types of collets available and their specific applications, as well as the properties of various collet materials and coatings, you can make informed decisions when selecting the right collet for your machining needs.

A collet is a cylindrical toolholder that grips cutting tools or workpieces with high precision. Essential in CNC machines, collets achieve tight tolerances, reduce runout, minimize vibration, and improve machining accuracy.Southwick & Meister, Inc. is one of the leading manufacturers of CNC collets, bushings, cutting tools, and more, serving customers worldwide with standard, semi-standard, and specialty products in standard, decimal, metric, and custom bore sizes.Powerful 4˚ taper collets provide improved performance holding tool shanks from 3/32″ to 1/4″ (3mm-6mm). Perform fast slim fit tool changes using just the T-wrench. Why SlimFIT outperforms ER Collet Systems.ER collets are a type of tool holding device commonly used in CNC machines. They are designed to securely affix cutting tools like end mills, drills, reamers, etc in a CNC machine's spindle. ER collets come in different sizes, denoted by the number appended to the end of their name.

CNC collets are an essential component in machining, responsible for holding the tool in place and ensuring precision and accuracy in the cutting process. There are several types of CNC.

What are Collets? Collets are the critical connection between the cutting tool and the tool holder (also called a collet chuck). Most collets are round, cone-shaped, and slotted. Collets encircle the cutting tool shank to evenly distribute holding power around its center bore.

To choose the right collet, consider the shank size of your tools, the required precision, the type of material to be machined, and your CNC machine’s specifications. It’s important to select a collet that matches your tool’s diameter and offers the appropriate clamping force and accuracy.A CNC collet is a clamping device used widely in machining operations to hold onto a workpiece or cutting tool securely. It fits inside a spindle, chuck, or holder of a machine tool, providing a precise and tight grip that prevents the object from moving during the machining process.

turquoise metal tool box

CNC machine collets are precision-machined cylindrical devices used to hold and secure cutting tools in place within a CNC machine. They provide the necessary grip to prevent tool slippage and ensure accurate machining operations. By understanding the different types of collets available and their specific applications, as well as the properties of various collet materials and coatings, you can make informed decisions when selecting the right collet for your machining needs.A collet is a cylindrical toolholder that grips cutting tools or workpieces with high precision. Essential in CNC machines, collets achieve tight tolerances, reduce runout, minimize vibration, and improve machining accuracy.

tv mount electrical box

Southwick & Meister, Inc. is one of the leading manufacturers of CNC collets, bushings, cutting tools, and more, serving customers worldwide with standard, semi-standard, and specialty products in standard, decimal, metric, and custom bore sizes.Powerful 4˚ taper collets provide improved performance holding tool shanks from 3/32″ to 1/4″ (3mm-6mm). Perform fast slim fit tool changes using just the T-wrench. Why SlimFIT outperforms ER Collet Systems.ER collets are a type of tool holding device commonly used in CNC machines. They are designed to securely affix cutting tools like end mills, drills, reamers, etc in a CNC machine's spindle. ER collets come in different sizes, denoted by the number appended to the end of their name.

types of collets chart

sealed collet vs non

Junction boxes are used when electrical circuits branch off in multiple directions or when circuits are being extended. The junction box must have a removable cover to create a complete enclosure, and the cover should remain accessible and not be covered with drywall or other materials.

cnc machine collet|collet identification chart