sheet metal quality inspection Visual inspections—The most basic form of inspection, it involves inspectors examining the sheet metal parts for any visible defects, such as scratches, dents, surface irregularities, or inconsistencies in color and finish. $14K+

0 · surface inspection system for steel

1 · surface finish inspection equipment

2 · sheet metal quality checklist

3 · sheet metal inspection checklist

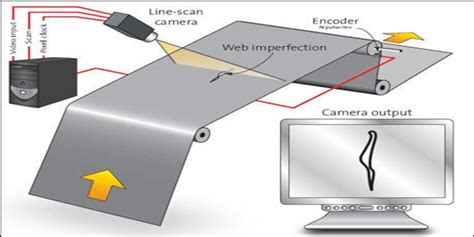

4 · scanning surface inspection system

5 · inspection lights for surface defects

6 · freescan combo 3d scanner

7 · automated optical surface quality inspection

Choose from our Trex Ready® series with six designer-curated designs or customize your outdoor space to your own unique needs. We make it easy to add long-lasting luxury with our stainless steel cabinetry. There’s more to an outdoor kitchen than a grill island and a sink.

A sheet metal inspection and reverse engineering solution using the InspecVision Planar2D - the worlds fastest 2D measurement system. Manufacturing sheet metal parts can be particularly difficult. The production cost per component is very low compared with other industries such . Visual inspections—The most basic form of inspection, it involves inspectors examining the sheet metal parts for any visible defects, such as scratches, dents, surface irregularities, or inconsistencies in color and finish.

Explore essential quality metrics for sheet metal fabrication drawings. Ensure precision and efficiency with expert insights from HitechDigital.Discover how precision measurement in sheet metal stamping operations reduces costly errors and improves customer satisfaction, improving profitability.Quality Assurance in the Sheet Metal Industry. Unlike quality control (QC), quality assurance (QA) focuses on preventing issues during manufacturing operations rather than identifying them after they occur. By evaluating existing processes, .Our sheet metal inspection ensures precision and quality. Elevate your projects with our comprehensive quality assurance. Get your free quote and learn more!

AI and machine learning are revolutionizing sheet metal inspection. Instead of just spotting defects, they’re now predicting and heading off issues before they happen. Using past data, these tools are shifting from just fixing . Machine learning and AI are revolutionizing sheet metal inspection. Instead of just spotting defects, they’re now predicting and heading off issues before they happen. Using past .Perform sheet metal inspections with our award winning Planar 2D Inspection Machine, the fastest and most automated 2D inspection system in the world.

At FirstPart, we have developed a highly effective inspection and quality control technique that helps to appraise all incoming raw materials and finished products. Our quality control process combines expertise and experience with advanced equipment for measuring and reviewing client specifications against produced samples before final runs. The flaw detection of metal sheet on machined metal sheet has become a main method and in product quality. Means inspection needed as the processing needs of modern industrial products continue to develop. Most businesses, on the other hand, still rely on manual visual inspections.Complete Quality Assurance and Inspection Department: Aldine Metal Products is committed to achieving customer satisfaction and expectations through delivering products on time, meeting customer product specifications and continuously improving our process in metal fabrication quality control through sheet metal inspections. This ensures sheet metal components meet the escalating quality standards essential for staying competitive in an ever-evolving industry. As these algorithms evolve and mature, expect sharper accuracy in defect detection. Advanced 3D scanning technologies and software solutions are driving a paradigm shift in the quality inspection industry.

Planar is a 2D inspection machine that allows manufacturers to simply and quickly verify product quality by performing 2D inspection, CAD comparisons & reverse engineering in seconds. View All. . Sheet Metal Inspection Difficulties. When producing small production runs for more mundane applications, a typical sheet metal part IS often painted .Quality Assurance in the Sheet Metal Industry. Unlike quality control (QC), quality assurance (QA) focuses on preventing issues during manufacturing operations rather than identifying them after they occur. By evaluating existing processes, detecting pain points, and implementing appropriate solutions, industry professionals can minimize the .

Re: Sheet metal inspection - restrained or unrestrained My $.02 Per Boeing Standards, you may restrain the part using not more than 5 Lbs of pressure, "Finger pressure as we call it". Sheet metal, due to the nature of it, tends to bow, and in aerospace applications, sheet metal parts are assembled or riveted to the final assy at the plant. Quality control doesn’t end when the parts come off the production line and pass inspection. The final step of the quality program is packing the finished components so that they are properly protected when shipped and arrive safely at their destination. . flat sheets of metal but may not be the best choice for 2-axis cutoff of small parts. Quality control in sheet metal fabrication detailing entails several challenges that can significantly impact the final product’s integrity and client satisfaction.Here are key challenges and their implications: Balancing Cost and Quality: Achieving the right balance between cost and quality is crucial. High-quality standards often increase costs, while cost-cutting can .At Aldine Metal Products, we take pride in our rich legacy of delivering precision-engineered metal solutions to a wide range of industries. With a commitment to quality, innovation, and reliability, we have earned our reputation as a trusted partner for commercial, military, electronic, medical equipment, packaging equipment, and railroad sectors.

Sheet metal inspection is the process of evaluating and verifying the quality, accuracy, and conformity of sheet metal parts to ensure they meet the specified design requirements and industry standards. Although coordinate measuring machines (CMMs) and laser scanners are regularly found in quality assurance (QA), they are poorly suited to sheet metal inspection. So much so sheet metal manufacturers often end up leaving them unmanned and going back to using callipers. CMMs are more expensive to run than more up-to-date systems as they .Quality Control & Inspection ZhongXin Group is a leading metal fabrication company in Europe, delivering a top-quality service from design, through manufacture to assembly and delivery. Superior quality and customer focus are evident in everything that the ZhongXin Group manufactures, tests and delivers. We’re ISO 9001:2015 accredited and committed to .

screwless junction box cover

The automated solution from ZEISS, ATOS ScanBox, allows a fast and efficient inspection of sheet metal parts. Its non-contact measuring system can be used in the sheet metal forming process to guarantee consistent quality assurance .

surface inspection system for steel

Quality inspection is vital because automotive sheet metal must withstand stress and fatigue over the vehicle’s lifetime. Apart from ensuring safety, quality inspection also ensures that the visual standards of consumers .

Quality Inspection. At Pinzhihao Precision, our core focus lies in delivering exceptional CNC machining services, sheet metal manufacturing, and UV printing. Central to our commitment is an unwavering dedication to maintaining the highest standards of quality throughout our operations.%PDF-1.5 %âãÏÓ 533 0 obj > endobj 557 0 obj >/Filter/FlateDecode/ID[6101BDA915E51344AD07A1CD809BAE8D>]/Index[533 50]/Info 532 0 R/Length 113/Prev 191518/Root 534 .Complex sheet metal component shapes are achieved through precise, programmed machinery. Cellular Manufacturing. DAWSON operates leanly with work stations and equipment arranged to accommodate a one piece flow, for efficient manufacturing and quality assurance. Quality & .

sealed vs ported sub box for metal music

Sheet metal inspection equipment will check the quality at the early stages of your processes. Confirm the part is worthwhile. Determine if you will send it to scrap metal before applying all the labour at every other stage of the process.Understanding Sheet Metal Quality. Sheet metal evaluation encompasses various aspects, including: Material inspection: Verifying composition and adherence to specifications. Thickness measurement: Ensuring uniform viscosity across the sheet. Surface inspection: Identifying scrapes, flaws, and inconsistencies. A reliable in situ inspection of working rolls’ surface quality requires fast roughness measurements with >0.5 m 2 /min on a nanometer scale. A speckle-based measurement approach is realized using a high-speed pulse laser and FPGA-based image processing to inspect surface areas with a diameter of 1 cm without motion blur with 200 Hz.Advantage Metal Products provides fabrication inspection on all of your custom precision sheet metal products so you get a high-quality product every time. Our Partnered Companies: Linkedin Facebook Instagram. Call Us Today: +1 (925) 455-8789. . sheet metal fabrication, or inspection services, we have you covered. Contact our team to get .

We're professional manufacturer to produce the best quality Metal Detectors, X-ray Inspection System, Checkweighers, Combination Systems, Sheet Metal Fabrication Products, and more - All Tailored to Fit Your Needs. . Being an industry leader in the custom fabrication, finishing of sheet metal products and product inspection equipment. Architectural Sheet Metal Quality Assurance Guide. Architectural Sheet Metal Inspection Guide. Architectural Sheet Metal CADD Drawings. This site Uses Cookies. This site uses cookies to store information on your computer. Some are essential to make our site work; others help us improve the user experience. By using the site, you consent to .127 Quality Control Sheet Metal Inspector jobs available on Indeed.com. Apply to Quality Control Inspector, Quality Assurance Inspector, Supplier Quality Engineer and more! . The Quality Control Inspector will perform inspection of electronic components, sheet metal fabricated items, printed circuit boards and hardware to ensure .Visual inspection for surface imperfections will be the responsibility of all PTI personnel. Verification of any non-conformance shall be conducted by Quality and/or Manufacturing personnel or its designee. It shall be the responsibility of the Quality Department to assure the requirements outlined in this procedure are complied with.

surface finish inspection equipment

$2,500.00

sheet metal quality inspection|inspection lights for surface defects