sheet metal slitting process Slitting, in the context of sheet metal manufacturing, is a shearing operation . Instantly find drill bit conversions, just refer to one of our tables for standard gauges, fractional inch sizes and centre drill bit sizes. Every drill size chart you’ll ever need is .

0 · steel slitter machine

1 · slitting process in sheet metal

2 · slitting operation in sheet metal

3 · slitting machine process

4 · slitting machine for steel coil

5 · hand slitter for sheet metal

6 · hand held sheet metal slitter

7 · coil slitting process

Determine the load capacity of the wall sconces (in watts or amps) to ensure that the junction box can safely support the electrical load. The junction box should have a sufficient rating to accommodate the power requirements of the sconces.

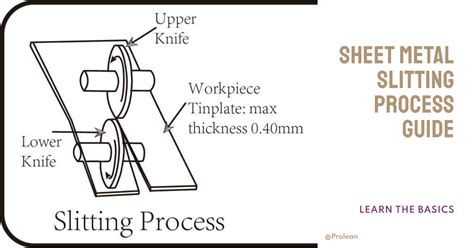

This article explores the slitting process in sheet metal manufacturing, covering the basics, material selection, machine configuration, execution of the slit, coil inspection, and packaging and delivery.Slitting, in the context of sheet metal manufacturing, is a shearing operation .Slitting is a crucial process in sheet metal fabrication, specifically applied to sheet metal coils. This technique involves cutting a wide coil of sheet metal into narrower strips, contributing to .

Sheet Metal Slitting. Slitting is a shearing process in which the sheet metal is cut by two opposing circular blades, like a can opener. Slitting can be performed in a straight line or on a curved path. The circular sheet metal cutters can be . In the ever-evolving world of sheet metal fabrication, innovation is the key to staying ahead of the curve. Modern sheet metal decoilers are no exception, with cutting-edge features that are revolutionizing the industry. Automated Loading and Unloading Traditionally, loading and unloading sheet metal coils was a manual and time-consuming process.The slitting process can be done with a variety of metals, including steel, aluminum, and stainless steel. The thickness of the metal being slit can vary, from thin sheet metal to thick steel plate. The width of the resulting metal strips can . This article will focus on the topic of steel slitting and how the slitting process works. Steel slitting is a steel manufacturing process wherein a coil of steel is slit into the lengths and widths specified by the end application. This process requires machinery lines equipped with a decoiler, slitter, and a recoiler — to achieve the end .

The process involves decoiling the wide sheet metal, performing a slitting operation, and recoiling the narrower strips. These machines are typically used for materials like steel, aluminum, and other sheet metals. As a leading supplier of slitting machines, we offer advanced solutions tailored to our clients’ specific requirements, ensuring .

steel slitter machine

Metal slitting is a process which cuts a wide coil of metal into a number of narrower coils. The slitting process is: Restricted to cutting relatively thin materials (0.001 to 0.125 in.) Available for use on both ferrous and nonferrous metals Available for both sheet and coil roils Metal slitting can be done for stainless [.]Download scientific diagram | (a) Scheme of the slitting process; (b) typical defects in the sheet sheared edge from publication: Application of variational and fem methods to the modelling and . The blades are also known as “slitting knives” and are modified to produce various widths of sheet metal strips. What is interesting is that the metal is not cut as you might imagine. The process of high-quality metal slitting can be described better as metal fracturing. Two rotating blades – one upper and one lower – begin the fracture .A fast slitting process free of deformation The material is not deformed during processing, meaning that you achieve the highest cutting quality. . To cut sheet metal, we can offer you sheet metal cutters, slitting shears, and nibblers. Find out more about the benefits to you here. Construction industry.

Slitting is an essential process in the metal industry. Discover the basics of what steel slitting entails and how it benefits metal producers and consumers. . For example, rather than purchasing a standard width sheet, slitting allows custom widths like 15.875″ for specific parts or roll-forming applications. 3. PRECISION TOLERANCES.

slitting process in sheet metal

KingReal is one of the manufacturers and suppliers in China's professional sheet metal slitting machines.We can provide customers with price lists and discount quotation. +86-13702855825 [email protected] . Other Coil Process Line. Metal Perforation Line; Press Feeder Equipment; New Products. Stainless Steel Coil Slitting Machine.About Us. Founded in 1993, Doğusan Metal Sanayi ve Tic. A.Ş. continues to be the solution partner of its customers with cold sheet rolling, Coil Sheet Uncoiling, Coil Sheet Cut to Length, Coil Sheet Slitting, Flat Wire Production, Cable Armoring Tape production and flat metal product sales in its factory with a production area of 4,000 m2 in İkitelli.

Slotting is a sheet metal process where a slot is put in the metal to do its job. Also known as slitting, the machines used in the process are called slitting machines. The process involves cutting notches in the steel sheets and removing the excess metal with a chisel. 9. Bending. Sheet metal bending refers to the process of shaping the metal .

Generally, Sheet metal cutting refers to splitting a single metal sheet into two or more pieces.But, it also involves the removal of unwanted parts from a sheet using shear force, heat, or any other form of energy. The cutting process requires high pressure at the cutting position, which can fracture the sheet from the designated area to create the desired shape.Slitting is a process used to cut a wide coil of metal into several narrower coils. The process is primarily used to cut thin materials lengthwise and features a machine fitted with circular blades. . Stages of Metal Sheet Slitting. Storage .

Steel strip cutting is a crucial process in various industries, including automotive, construction, and packaging. Slitting coils with precision is essential to ensure the dimensional accuracy, surface quality, and overall performance of the final product. This comprehensive guide provides a step-by-step approach to achieve precise steel strip cutting. Choosing the Right . The manufacturing process of sheet metal decoilers involves a series of intricate steps that transform raw sheet metal into various finished products. . Unlocking Productivity with Steel Slitting Line Machines In the realm of metal processing, steel slitting line machines have emerged as pivotal tools for businesses seeking to revolutionize .KingReal as the professional sheet metal perforating machine manufacturer and suppliers, Welcome to buy sheet metal perforating machine from our factory. Since establishment, our company is focused oncoil processing machines, such as coil slitting line machine and cut-to-length-line machine development, design and production.

drywall mounted ceiling junction box

Application is made to slitting of 3D anisotropic sheet by studying the influence of some process parameters as the shape of the knives, the sheet thickness and the initial residual stress fields. The proposed methodology is shown to be very useful and helpful when dealing with a “virtual” improvement of any slitting process. Steel strip slitting machines are vital equipment in the metalworking industry, used to cut metal coils into narrow strips of various widths. . and remote access capabilities, enabling operators to optimize the slitting process remotely. Safety and Maintenance. . Choosing the Right Sheet Metal Folding Machine for Your Business Needs

This article discusses the operating principles, types, and applications of shearing and slitting of different forms of steel, including plates, flat sheets, bars, coiled sheet and strips. This process helps facilitate further manufacturing and fabrication processes of aluminum sheet metal such a blanking, progressive die stamping, roll forming, tube manufacturing, to name a few. Slitting plays a crucial role in preparing coils of material for many different applications.The Marxman Pro Metal Slitter has the added benefit of auto knife setup, auto nesting, and optional part cut and label application capability. AUSTRALIA +61 3 55645333 USA 770-766-0880

Accuracy is the name of the game here, and the shearing sheet metal process helps to achieve that optimally. Many manufacturers also love the shearing metal process because it doesn’t take much heat or produce much waste. Compared to a lot of other metal forming processes, the sheet metal forming shearing process is known for being especially . Some slitting problems can be attributed to poor metal quality; however, it is much more common for the problems to be caused by other variables and factors during the slitting process. Slitting encompasses many variables, and most of them can be controlled. To achieve a good slitting result, each variable that can be controlled must be controlled. Sheet metal-operations - Download as a PDF or view online for free . deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting. Sheet metal workers use tools like dies and presses to perform these operations and shape the metal. . Deep drawing is a metal forming process in which . How does the metal slitting process work? Metal slitting is a metal-making process in which a roll of metal is cut to a length and width specified by the terminal application. This process requires a mechanical production line with uncoiler, slitter and coiler to achieve the final product: slitting metal reels, or “multiple reels.”

dual gang junction box installation

slitting operation in sheet metal

$14.99

sheet metal slitting process|steel slitter machine