cnc cutting machine risk assessment The first step in a CNC machine risk assessment is identifying the potential hazards associated with its operation. This section will discuss common risks such as mechanical hazards, . For decades now, Toyo Steel has produced high quality tool and utility boxes as well as other fine steel items for both home and professional use. Download / View Toyo Steel Co. linesheet 14 products

0 · safety of cnc machinery

1 · cnc machine shop safety

2 · cnc machine safety shield

3 · cnc machine safety risks

4 · cnc cutting machine safety

5 · are cnc machines safe

6 · are cnc machines dangerous

7 · accidents in cnc machines

The machining is excellent, the parts are absolutely perfect. They fit together .

The first step in a CNC machine risk assessment is identifying the potential hazards associated with its operation. This section will discuss common risks such as mechanical hazards, .However, with this advancement comes potential risks that need to be thoroughly assessed and managed. In this blog post, we will dive deep into the world of CNC machine risk assessment, . Occupational risk assessment is a primary prevention and health task in every workplace. This assessment is mainly intended to ensure the safety of employees and to .In this blog post, we will provide a comprehensive example of a risk assessment for CNC machines. By understanding and addressing these risks, manufacturers can create a safer .

In order of this risk assessment method plays significant role. The purpose of risk assessment to identify potential hazard and risk associated in the working area in order to keep workplace . Law requires from employers to assess occupational risk in workplaces. A well-executed occupational risk assessment promotes the improve-ment of working conditions and reduces a negative.

After conducting a machine risk assessment, strategies and machine-guarding techniques can be implemented to minimize or avoid danger and harm to workers and machines.Operation of the production organization is equipped with modern CNC machining centres as well as machines for material cutting-off. Quality of production is ensured by reliable control.

safety of cnc machinery

The aim of risk assessment is highlighting the safety aspects in cnc milling process. milling machining is one of the hazardous process in manufacturing industry which have multiple potential hazard so that we have applied risk .The first step in a CNC machine risk assessment is identifying the potential hazards associated with its operation. This section will discuss common risks such as mechanical hazards, electrical hazards, ergonomic hazards, and occupational health hazards.However, with this advancement comes potential risks that need to be thoroughly assessed and managed. In this blog post, we will dive deep into the world of CNC machine risk assessment, exploring different hazards, preventive measures, and the importance of maintaining a safe working environment.

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

Occupational risk assessment is a primary prevention and health task in every workplace. This assessment is mainly intended to ensure the safety of employees and to eliminate or partially reduce existing threats by taking appropriate remedies.In this blog post, we will provide a comprehensive example of a risk assessment for CNC machines. By understanding and addressing these risks, manufacturers can create a safer working environment and minimize the likelihood of incidents.In order of this risk assessment method plays significant role. The purpose of risk assessment to identify potential hazard and risk associated in the working area in order to keep workplace safe. For this purpose we have given countermeasures for . Law requires from employers to assess occupational risk in workplaces. A well-executed occupational risk assessment promotes the improve-ment of working conditions and reduces a negative.

After conducting a machine risk assessment, strategies and machine-guarding techniques can be implemented to minimize or avoid danger and harm to workers and machines.Operation of the production organization is equipped with modern CNC machining centres as well as machines for material cutting-off. Quality of production is ensured by reliable control.The aim of risk assessment is highlighting the safety aspects in cnc milling process. milling machining is one of the hazardous process in manufacturing industry which have multiple potential hazard so that we have applied risk assessment method to find out risk related to it and also given counter measures to reduce or eliminate risk in order .

The first step in a CNC machine risk assessment is identifying the potential hazards associated with its operation. This section will discuss common risks such as mechanical hazards, electrical hazards, ergonomic hazards, and occupational health hazards.However, with this advancement comes potential risks that need to be thoroughly assessed and managed. In this blog post, we will dive deep into the world of CNC machine risk assessment, exploring different hazards, preventive measures, and the importance of maintaining a safe working environment. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

Occupational risk assessment is a primary prevention and health task in every workplace. This assessment is mainly intended to ensure the safety of employees and to eliminate or partially reduce existing threats by taking appropriate remedies.

In this blog post, we will provide a comprehensive example of a risk assessment for CNC machines. By understanding and addressing these risks, manufacturers can create a safer working environment and minimize the likelihood of incidents.

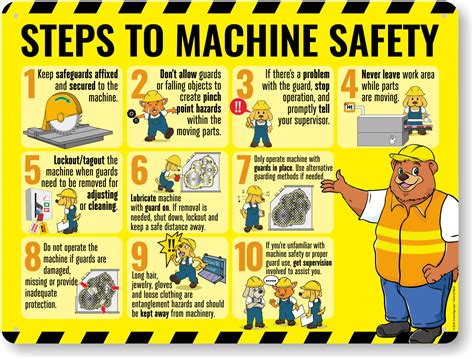

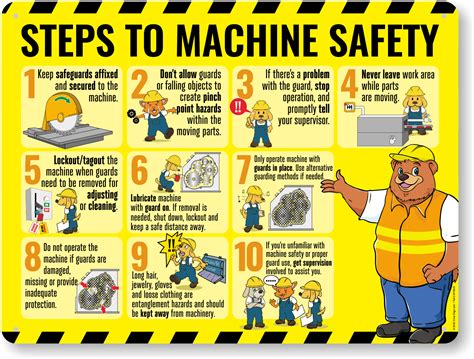

In order of this risk assessment method plays significant role. The purpose of risk assessment to identify potential hazard and risk associated in the working area in order to keep workplace safe. For this purpose we have given countermeasures for . Law requires from employers to assess occupational risk in workplaces. A well-executed occupational risk assessment promotes the improve-ment of working conditions and reduces a negative. After conducting a machine risk assessment, strategies and machine-guarding techniques can be implemented to minimize or avoid danger and harm to workers and machines.

Operation of the production organization is equipped with modern CNC machining centres as well as machines for material cutting-off. Quality of production is ensured by reliable control.

cnc machine shop safety

2-gang 4 in square metal electrical box cover

cnc machine safety shield

Distributor of industrial weighing equipment and components including electric junction boxes. Types include signal trim, excitation trim, and digital diagnostic junction boxes. Available in various models and specifications.

cnc cutting machine risk assessment|are cnc machines safe