how to get cnc machine work Get your Free CNC Expert Profile: CNCEXPERT.comIndustry advice from Titan on how to GET and KEEP your CNC Machines cutting chips and making parts. Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 mm. E6013 types electrode offer very good arc stability, easy-to .

0 · working principle of cnc machine

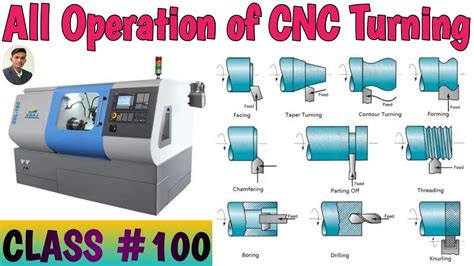

1 · operations of cnc machine

2 · how to use cnc machine

3 · how to use cnc

4 · how does cnc machining work

5 · cnc machine setup

6 · cnc machine process step by

7 · cnc machine operating instructions

Whether it’s small aluminum box, extruded aluminum box, stainless steel box, carbon steel box, die-cast junction boxes enclosures, or sheet metal box, we have 28 years of experience .

I'm helping out at my family's fairly newly-started CNC machine shop. Is there any advice on how I can help find clients/works? I'm fairly new to this industry so I'm basically just cold calling . In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your .How Does a CNC Machine Work? Operating a CNC machine involves setting up the machine, preparing the material, and inputting a design file. The machine’s software then interprets the .

Get your Free CNC Expert Profile: CNCEXPERT.comIndustry advice from Titan on how to GET and KEEP your CNC Machines cutting chips and making parts. Finding CNC machining work requires a combination of leveraging existing relationships, reconnecting with past contacts, and reaching out to new potential customers. .

First, let’s list some of the considerations you need to make to run a successful CNC machining business: Equipment: CNC machines, tooling, and work-holding devices. Facility: building construction or rent, utilities, and .

12 MINUTES. View 27 Comments. How To Start A CNC Shop: Everything You Need To Know. Watch on. Looking to start your own CNC business? Learn all the details you’ll need to think about from a company that .Nah, you just throw the vice on the table with tslots just like your ender 3 printer but bigger throw some parallels in it (basically sheet metal machines to be parallel to each other to hold up the work off the vice "floor" and a setup block (steel block cut exactly to 2" x4" x6") and then you use an "edge finder" "stick with a spring in it . Bought a hobby machine, or more accurately a machine for hobby (not always hobby machines), that did some side work while they held a day job. Then machining became a full time thing over time. Most of the time these people had their own products to sell and not necessarily just a machine shop taking orders making other people's stuff.If you know what machine(s)/ type of machine(s) your job needs to be run on call your local machine dealers (HAAS, Okuma, Mori Seki, etc.). And ask what shops in that area have those machines and/or might be job shops. I work at a job shop in Western NC and there are at least 2 others within a 5 mile radius.

Leasing works differently from business loans. With a lease, you’re not buying the equipment, you’re entering into a long-term rental agreement. Depending on the type of lease you choose, (finance lease or operating lease), you may have the option to buy the CNC machinery at contract end for a pre-agreed sum, (which could be as low as but is typically the residual .If you have the money, get a small CNC router and learn how it works. YouTube tutorials are a great start, but if you want to work in the industry having some kind of certification will get you a job much faster. TLDR: Starting CNC machining from scratch is very hard, but so are most jobs. Keep Your CNC Machines Running at Full Capacity. Finding CNC machining work requires a combination of leveraging existing relationships, reconnecting with past contacts, and reaching out to new potential customers. By focusing on these top three strategies, you can increase your chances of getting more CNC projects and keeping your business .I'm in north california bay area and looking at both careers, machinist over here have better pay (talking about k starting point, even for those with little experience), better benefits, work/life balance and work environment. Plus the weird schedules aircraft technicians have is not so appealing to me anymore.

Find Work and Workers Using CNC Recruitment Agencies. As America’s premier travel staffing company specializing in the trades, Skillwork matches tradesmen with employers across the country – like those wondering how to get CNC machine work and how to find CNC machinists. How to Get CNC Machine Work. If you’re a CNC machinist looking for .

3. Learn about the components and construction of CNC machines. CNC machines like lathes, mills, routers and drills are all the equipment to complete the machining operations on the material stock, get to know what is the machine composed of and the function of each component. 4.Hey I am a woodworker have a full shop and looking to get a cnc machine with a rotary. I have an omtech, full wood shop with pro grade stuff powermatic jet laguna etc. I want to spend 5-8k on a cnc machine to do everything from gun grips to cabinet doors to .I Australia most cnc work is billed out at a standard of per hour, sometimes lower or higher depending on job, machine, materials etc I was a cnc operator and laser cladding specialist, cladding 6mm thick coatings of tungsten carbide impregnated nickle onto mining equipment for wear resistance, using a 12kw fibre laser, billed at 400 per hour. Howdy, Im hoping to start up my own machine shop sometime in the near future (I'm a cnc machinist with 12+ years experience) but don't have the money for my own cnc machines yet. Is it possible (or a good idea) to start bringing in work for my shop before I have my own cnc's, then.

How Does a CNC Machine Work? A CNC machine works by following a computer-aided design (CAD) file, which is a digital model of the part or object that needs to be created. This CAD file is then converted into a set of numerical data, called G-code, that tells the CNC machine how to move. The machine can cut, shape, drill, or engrave materials . A CNC machine tool always has a sliding table and a spindle to control the position and speed. The table of the machine is controlled in the X and Y-axis direction and the spindle is controlled in the Z-axis direction. Driving System. The driving system of a CNC machine includes an amplifier circuit, drive motors, and ball lead screws.What Is a CNC Machine? CNC stands for computer numerical control; it is a process that allows for tool automation. While people may believe that CNC machinery is a small, bespoke set of automated machines, in reality, the CNC designation stretches across many different kinds of computer numerically controlled machine tools.A newbie’s guide to your electronic shop helper. CNC (Computer Numeric Control) technology is becoming more and more affordable. That’s not to say these machines are cheap, but for the investment of two to three thousand .

But for training to program CNC machines, I would work with Fusion360 as it's free and there is a massive community to help you learn. One thing you really need to understand about programming is your feeds and speeds and cutting pressure. This is what decides what types of toolpaths you can use for what types of materials and shapes.FAR better paying, less overall work and way less stress. Applications engineer is also a great way to work in CNC, make $$$, and travel the world. . I set up the cnc machines change out tooling, plus the bar loaders. I have to run a program check just to make sure there aren't any surprises. Get steel, stainless, and brass rods from the .

Jessie shows us a step by step process on how to set up a 5-Axis project using the DVF 5000 from DN Solutions. He then shows us the full process of machining.

If your a manufacture post what work and capabilities you have to offer here only! Please post your email, website and a good description of your company. . Manual Machine Work. . For quotes requiring CNC routing. Threads 74 Messages 320. Threads 74 Messages 320. A. Baltic Birch And Mdf Cnc, Zip 37027. May 14, 2020; AaronReady; 4-Axis Cutting.

Plus it gave me knowledge of how the machines work and what they need to keep working. When the machine shop supervisor quit they sent me to GibbsCam so I could program and get the existing programs to the machines. It was shortlived because the company moved out of state. I tried to get a straight programming job after that and I couldn't do it.

Go with the flow . CNC workflow breaks down into four primary steps, each involving software. These steps may appear complex at first, with lots of settings and details to remember, but after working through the process a few times (and making a few mistakes) it becomes routine—and the creative possibilities open up.Small quantity fixturing, gages, and ground support tooling for the aerospace industry. The shop I work at is beyond laid back, flexible hours, lax policies. I show up to work in sweatpants everyday, making /hour with as much OT as I can muster. Early on really wanted to get into milling. Too much time invested in lathe work so I’m stuck now.

One of the machines is a 3+2 CNC machine that can take advantage of many cutting geometries. The company has plans to purchase a full 5-axis machine in the near future. How much has all this equipment cost? “Roughly half a million dollars,” says Spurling.

replacing distribution box in septic

Even if the part only takes 4 minutes to machine, you still have to do all the work that goes into it before hand, still has to go through QA. In most cases it's not that much more expensive to make 10-1000 parts vs just making a single one off part. . CNC machines can cost hundreds of thousands of dollars, parts require hours to make so you .How to Get Started With CNC: This instructable is a lesson in my free CNC Class. To enroll, click here. In this lesson, we'll go over how to get started with CNC. . I've been 3D modeling for over 13 years, and I can tell you honestly that this program is perfect for the kind of work I do: furniture, toys, machines, household products, etc. It .What is a CNC machine? Scrolling through your social media, you have probably come across videos of machines carving materials into various shaped objects in.

working principle of cnc machine

operations of cnc machine

This is the making of our DIY metal + Wood Hanging Kitchen Cabinet, You can checkout the chapters below to skip different steps of the build.This is the most.

how to get cnc machine work|cnc machine operating instructions