cnc grinding machine bit drawing Milling bits, also known as milling cutters, are tools used in manual and CNC machines for cutting into materials like metal, plastic, or wood. They spin around and shave off parts of the material to shape it or create holes. . Sheet metal welding is done by heating two thin sheets of metal to melting point. The melted sheets are then skillfully joined together using a torch to form the desired shape and specifications. Clear the work area of any flammable materials and .In this article, I am going to explain the fundamental ways of how to weld sheet metal that even professionals can follow. I have also put together a list of best welders for .

0 · technical drawings for cnc engineering

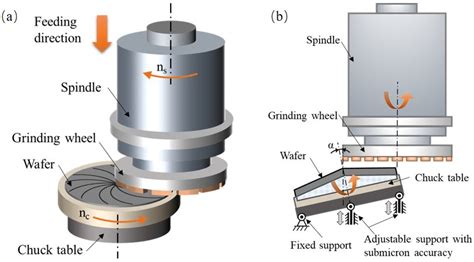

1 · grinding process diagram

2 · grinding process design

3 · engineering drawing for cnc manufacturing

4 · cnc machining drawings

5 · cnc drawings

6 · cnc drawing process

7 · cad for cnc machining

Stations, Signal Boxes and Junctions Distance from Signal Box above Loops and Refuge Sidings Notes; Up Down; Maximum permissible speed 60 m.p.h. Werrington Junction to Boston Maximum permissible speed 65 m.p.h. Boston to Grimsby: 1 – ↓: Werrington Junction – 2: ↑: ↓: Peakirk Station: 2m 258yds: URS 52: 3: ↑: ↓: St. James Deeping .

This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts . A CNC grinding machine can be programmed to have a path with complex movements controlled by a computer. The feed direction can be in an X axis or a Z axis, or . In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques .In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best .

Milling bits, also known as milling cutters, are tools used in manual and CNC machines for cutting into materials like metal, plastic, or wood. They spin around and shave off parts of the material to shape it or create holes. .The P20-CNC Profile Grinder provides fast, high-performance profiling for HSSmoulder heads, brazed cutters, CNC router bits, and carbide inserts: Four Axis Grinding – X, Y, A, and B; Requires No Templates – Grinds Directly from .

Production cannot begin without a blueprint. This guide explains what it is and what are the crucial features of a blueprint. Explaining different symbols and various lines on a machining drawing. Learning to read blueprint symbols is .Discover how precision CNC grinding machines can maximise productivity and ensure high levels of surface quality.

CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming . Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8. This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of .

A CNC grinding machine can be programmed to have a path with complex movements controlled by a computer. The feed direction can be in an X axis or a Z axis, or both. Non-CNC grinders have simple left/right and in/out movements. In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering.In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best practices from our engineers.

Milling bits, also known as milling cutters, are tools used in manual and CNC machines for cutting into materials like metal, plastic, or wood. They spin around and shave off parts of the material to shape it or create holes. They .The P20-CNC Profile Grinder provides fast, high-performance profiling for HSSmoulder heads, brazed cutters, CNC router bits, and carbide inserts: Four Axis Grinding – X, Y, A, and B; Requires No Templates – Grinds Directly from DXF CAD Files • Heavy Duty 10 HP Motor for; Continuous Operation

Production cannot begin without a blueprint. This guide explains what it is and what are the crucial features of a blueprint. Explaining different symbols and various lines on a machining drawing. Learning to read blueprint symbols is challenging.

Discover how precision CNC grinding machines can maximise productivity and ensure high levels of surface quality. CNC grinding machines offer straightforward programming and efficient operation, making them ideal for precision manufacturing. Utilizing G-code and M-code, along with CAM software, simplifies the programming process and minimizes errors. Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8.

technical drawings for cnc engineering

This guide delves into the basics of machining drawings, their importance, and the essential elements of a CNC machining drawing. You will also learn why you need to prepare a technical drawing when sourcing parts and the importance of .

A CNC grinding machine can be programmed to have a path with complex movements controlled by a computer. The feed direction can be in an X axis or a Z axis, or both. Non-CNC grinders have simple left/right and in/out movements. In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering.In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best practices from our engineers.

Milling bits, also known as milling cutters, are tools used in manual and CNC machines for cutting into materials like metal, plastic, or wood. They spin around and shave off parts of the material to shape it or create holes. They .

The P20-CNC Profile Grinder provides fast, high-performance profiling for HSSmoulder heads, brazed cutters, CNC router bits, and carbide inserts: Four Axis Grinding – X, Y, A, and B; Requires No Templates – Grinds Directly from DXF CAD Files • Heavy Duty 10 HP Motor for; Continuous OperationProduction cannot begin without a blueprint. This guide explains what it is and what are the crucial features of a blueprint. Explaining different symbols and various lines on a machining drawing. Learning to read blueprint symbols is challenging.Discover how precision CNC grinding machines can maximise productivity and ensure high levels of surface quality.

grinding process diagram

WBM has been a leader in the distribution of stainless propeller shafting since 1976. Stocking the full range of Aqualoy shafting from ¾” through 8” diameter and up to 32’ in length, we offer quick, reliable delivery from our three distribution centers. WBM offers top-of-the-line manufactured parts at competitive prices.

cnc grinding machine bit drawing|grinding process diagram