cnc lathe machine report It discusses the history and evolution of CNC machines from the 1940s to present day. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback . An apprenticeship test (or pre-apprenticeship test) is designed to assess candidates applying for an apprenticeship in one of the labor unions across the U.S. and Canada. Common examples are the IBEW Test (electricians), the EIAT (elevator mechanics), and .

0 · cnc turning program examples pdf

1 · cnc turning machine programming pdf

2 · cnc turning cycle program pdf

3 · cnc programming PDF free download

4 · cnc programming For Dummies pdf

5 · cnc machine parts list pdf

6 · cnc machine operation manual pdf

7 · cnc lathe manual pdf

We’re proud to say our structural steel fabricating plant is AISC certified. With a solid team, the right machinery, and a focus on getting the job done right, we save our customers time and .

The report includes sections on CNC construction details, coordinate systems, positioning of the machine origin, motion control systems, part programming, and advantages .It discusses the history and evolution of CNC machines from the 1940s to .

It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and .In a CNC Lathe Machine, the work piece mounted to the Chuck is rotated in rpm. The tools then approach the material and cut it according to the coordinate . It discusses the history and evolution of CNC machines from the 1940s to present day. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback . The report includes sections on CNC construction details, coordinate systems, positioning of the machine origin, motion control systems, part programming, and advantages of CNC machines. It also provides acknowledgements, a preface, index, and several chapters discussing topics like numerical control and applications of CNC.

It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and set up the CNC to create a graphical cutting view of the piece P-34 and Tension Specimen.

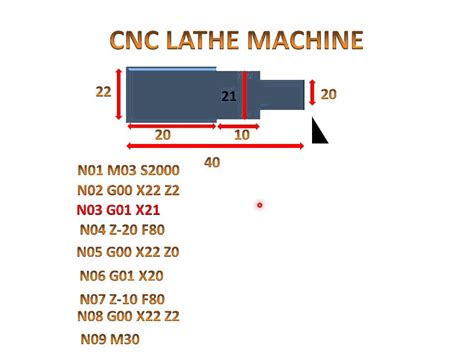

In a CNC Lathe Machine, the work piece mounted to the Chuck is rotated in rpm. The tools then approach the material and cut it according to the coordinate and codes programmed. Lathes create the surface cylindrical parts using outside and inside diameter cutting tools of different sizes and shapes.

It discusses the history and evolution of CNC machines from the 1940s to present day. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit.CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries. CNC is the automated control of machining tools by means of a computer. A CNC machine alters a blank piece of material to meet precise specifications by following programmed instructions and without a manual operator. Similarly, the CNC lathe machine uses a word address format for programming and run the machine.

The document provides information about operating a CNC lathe machine. It discusses the objectives of learning to use the lathe, safety precautions, tools used, the procedure for operating the lathe through coding, and examples of G-codes.The document provides an introduction to lathe machines. It discusses the history and evolution of lathe machines from ancient Egypt to modern computer numerical controlled (CNC) lathes. It then describes the basic components of a lathe machine and different types of .

A CNC machine can process a piece of materials such as metal, ceramic, composite and another types of material to meet specifications by following the coded programming instruction and without manual operator.

The experiment was successful in achieving the objectives and generating NC code to machine a part, while following safety regulations for CNC operation. The document discusses CNC milling objectives, introduction, apparatus, safety procedures, and experimental procedures. The report includes sections on CNC construction details, coordinate systems, positioning of the machine origin, motion control systems, part programming, and advantages of CNC machines. It also provides acknowledgements, a preface, index, and several chapters discussing topics like numerical control and applications of CNC.

It explores the coding, usage and set up of a Computer Numerical Controlled (CNC) machine. The purpose of this experiment was to be able to code and set up the CNC to create a graphical cutting view of the piece P-34 and Tension Specimen.In a CNC Lathe Machine, the work piece mounted to the Chuck is rotated in rpm. The tools then approach the material and cut it according to the coordinate and codes programmed. Lathes create the surface cylindrical parts using outside and inside diameter cutting tools of different sizes and shapes.

It discusses the history and evolution of CNC machines from the 1940s to present day. The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit.CNC lathe machines ensure that parts retain their dimensional stability throughout the production process. This means that the parts produced are not only precise but also stable and reliable, which is essential for critical applications in various industries.

cnc turning program examples pdf

CNC is the automated control of machining tools by means of a computer. A CNC machine alters a blank piece of material to meet precise specifications by following programmed instructions and without a manual operator. Similarly, the CNC lathe machine uses a word address format for programming and run the machine.The document provides information about operating a CNC lathe machine. It discusses the objectives of learning to use the lathe, safety precautions, tools used, the procedure for operating the lathe through coding, and examples of G-codes.The document provides an introduction to lathe machines. It discusses the history and evolution of lathe machines from ancient Egypt to modern computer numerical controlled (CNC) lathes. It then describes the basic components of a lathe machine and different types of . A CNC machine can process a piece of materials such as metal, ceramic, composite and another types of material to meet specifications by following the coded programming instruction and without manual operator.

junction box outdoor 2 double pole

junction box price flipkart

Up for sale is a vintage Wilco cash box made by Union Steel Chest Corporation in the USA. This silver-colored cash box features the Wilco brand a great addition to any .

cnc lathe machine report|cnc machine parts list pdf