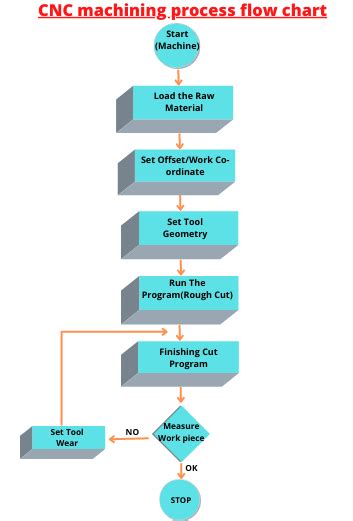

cnc machining process flow chart In this section, we will introduce strategies for optimizing CNC machining efficiency using the process flow chart. Topics covered will include tooling selection, machine programming, and . The TwoTrees TTC-450 Pro CNC Router Machine is a device that uses bits as tools to carve designs on wood, MDF, plywood, resin, PVC, ABS, carbon fiber, acrylic, .

0 · milling machine block diagram

1 · machine manufacturing process flow chart

2 · cnc setup procedure

3 · cnc milling machine diagram

4 · cnc mill axis diagram

5 · cnc machining handbook pdf

6 · cnc machine schematic diagram

7 · cnc axis diagram

During our investigation, we discovered an abandoned shipment through a Diplomat from United Kingdom which was transferred from JF Kennedy Airport to our facility here in .

Step-by-Step CNC Machining Process. 1. Designing the CAD Model. The first step in CNC machining is creating a detailed CAD (Computer-Aided Design) model of the part to be manufactured. This digital model serves as the .In this section, we will introduce strategies for optimizing CNC machining efficiency using the process flow chart. Topics covered will include tooling selection, machine programming, and .

CNC Machining Process Guide The following standard machining processes are among the most common techniques used by machine shops today. While many other processes are in use, .

electrical box supplies

CNC machining is a widely used manufacturing technique that involves the use of computer-controlled machines to shape and fabricate various materials. From metal to plastics, CNC .One of the critical steps in the CNC machine process is setting up the machine and calibrating it to ensure accuracy and precision. Discover the step-by-step procedures to set up a CNC . When planning a CNC machining process there are many considerations and options to choose. From cutting tool selection to cutting parameters, the choices have a major effect on the end results.CNC machining is a manufacturing process which utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock material—e.g., metal, plastic, wood, .

Understand the CNC manufacturing workflow with our informative infographic. See how it all fits together at CNCCookbook.

milling machine block diagram

From design and engineering to packaging and shipping, a comprehensive process flow chart can help streamline the CNC machining process and improve the quality and consistency of the.Although CNC products can be small, quality in manufacture is crucial. Draw a flowchart similar to the one below. This should explain every stage of the manufacture of a product you have .

One of the critical steps in the CNC machine process is setting up the machine and calibrating it to ensure accuracy and precision. Discover the step-by-step procedures to set up a CNC machine, including homing the machine, setting work offsets, and tool length compensation. Understand the importance of spindle calibration and alignment as well. 6.In conclusion, CNC machining is a complex but highly efficient manufacturing process. It involves several crucial steps, from designing the CAD model to performing the actual machining operations and completing necessary post-processing tasks. The precision and repeatability offered by CNC machining make it a preferred choice for various .

Production & Manufacturing Process, Value chain and System analysis tools. . CNC Process. by nimesh perera. Edit This Template. . You can easily edit this template using Creately's flowchart maker. You can export it in multiple formats like JPEG, PNG and SVG and easily add it to Word documents, Powerpoint (PPT) presentations, Excel or any .

CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product. The CNC machine removes parts of the workpiece by machining operations such as turning, drilling, or milling, according to codes (g-code and m-code) obtained from the CAD model and containing . When planning a CNC machining process there are many considerations and options to choose. From cutting tool selection to cutting parameters, the choices have a major effect on the end results. Here is what it might take to define a CNC toolpath: Job Name. Part Number. Part Revision. Stock Size X. Stock Size Y.

processes in CNC machining, most likely because it is so versatile. Using a single tool, machine shops can create contours, shapes and angles on the surface of a workpiece. Milling can completely transform a piece of metal stock into a finished part of nearly any complexity. The milling process in CNC machining consists of removing material with a

Quality control is an integral part of the CNC machining process flow. During and after machining, the produced part undergoes rigorous inspections to verify its accuracy and adherence to the CAD .CNC machining processes are used in a wide range of industries including aerospace, automotive, medical and industrial manufacturing to produce a wide variety of components. Its versatility and reliability make it an ineffective tool in modern manufacturing, and it is likely to continue to play an important role in the industry for years to .ConceptDraw is Professional business process mapping software for making process flow diagram, workflow diagram, general flowcharts and technical illustrations for business documents. It is includes rich examples, templates, process flowchart symbols. ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart .

ConceptDraw is Professional business process mapping software for making process flow diagram, workflow diagram, general flowcharts and technical illustrations for business documents. It is includes rich examples, templates, process flowchart symbols. ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart .CNC machining process planning productivity – a qua litative survey S Anderberg 1, T Beno 1,2, L Pejryd 1,3 1University West, Department of Engineering Science, Trollhättan, Sweden 2Volvo Aero, Trollhättan, Sweden 3Production Technology Centre, Innovatum AB, Trollhättan, Sweden [email protected] ABSTRACT Process planning is the link between design and .

electrical box thats not hollow

Download scientific diagram | Technological flow of CNC machining process [6] from publication: Development of CNC Program for Piston Production | Development of a computer numerical control .CNC machining has become an integral part of various industries, as it offers precision, efficiency, and versatility when it comes to manufacturing custom parts and components. This manufacturing process has evolved from the numerical control (NC) machining process, which used punched tape cards to control machinery. CNC stands for Computer. This blog explores the best practices for quality control in CNC machining and provides insights on reducing costs to help you stay efficient in manufacturing industry operations. Implement Statistical Process Control (SPC) Statistical process control (SPC) is a data-driven method for monitoring and controlling CNC machining.CNC machining processes are used in a wide range of industries including aerospace, automotive, medical and industrial manufacturing to produce a wide variety of components. Its versatility and reliability make it an ineffective tool in modern manufacturing, and it is likely to continue to play an important role in the industry for years to .

CNC machining flow chart in CNC machining process: CNC machining process is based on production needs. After opening, some small parts such as accessories can be punched and then cut or CNC processed. This is a lot in the production of eyeglass accessories auto parts. The container is made by pressing the punch after the punching, and then . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials.; Types of CNC machines: .

machine manufacturing process flow chart

cnc setup procedure

Download scientific diagram | CNC machining flow chart from publication: Mixed Teaching Innovation and Practice of “CNC Processing Process and Programming” Under the New Engineering Background .Electrical Diagram Of Cnc Machine ; Part Programming Flow Chart In Cnc Diag Pdf; Process Flowchart | Machining Process Basic Symbol Chart; Process Flowchart | Cnc Machine Charts; Process Flowchart | Cnc Machine Drawing Pdf; Process Flowchart | Cnc Machining Drawing Symbol Pdf File . ERD | Entity Relationship Diagrams, ERD Software for Mac and .Download scientific diagram | Overall flowchart of adaptive CNC machining technology from publication: Machining errors control method for near-net-shape jet engine blade CNC machining process .The CNC Machining Process. Now that we know what they do, how do they actually work? While these are computerized machines, there still needs to be some human intervention. Programming. For the computer to accurately perform the desired .

electrical box speaker wall mount

CNC machining processes are used in a wide range of industries including aerospace, automotive, medical and industrial manufacturing to produce a wide variety of components. Its versatility and reliability make it an ineffective tool in modern manufacturing, and it is likely to continue to play an important role in the industry for years to . At WayKen, we always understand the importance of quality control in CNC machining. Our comprehensive CNC machining services offer advanced technologies to ensure high-quality products. We also utilize a series of inspection tools and methods, including Coordinate Measuring Machines (CMM), traditional calipers and micrometers, surface finish .Download scientific diagram | The flowchart for CNC machining of parametric profiles. (a) The process from interpolation to motion control. (b) The desired and target tracking trajectories. from .

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions .Business Process Diagrams solution extends the ConceptDraw PRO BPM software with RapidDraw interface, templates, samples and numerous libraries based on the BPMN 1.2 and BPMN 2.0 standards, which give you the possibility to visualize equally easy simple and complex processes, to design business models, to quickly develop and document in details any . CNC machining flow chart in CNC machining process. The cnc in CNC machining means "computer data control" is simply "CNC machining". The English of CNC machining is the abbreviation of Computer Numberical Control, which is also called "computer 锣". Cnc processing is an automated processing method with high efficiency, high precision and high .

cnc milling machine diagram

Since I didn't pigtail the ground wire only ground the box, and all the receptacles can be back connected and accept two wires for each connection, and tightened by side screw, I don't even need the twist-on wire nut which save a lot of room in the box.

cnc machining process flow chart|cnc axis diagram