sheet metal flange forming Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets . Find thousands of white kitchen with Stainless Steel Cabinets ideas to help you come up with the perfect design for your space.

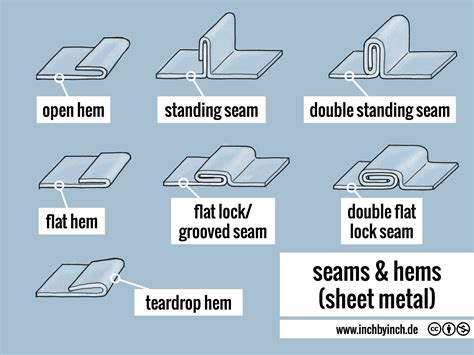

0 · types of sheet metal joints

1 · tdf flange forming machine

2 · sheet metal joining methods

3 · lap seam sheet metal

4 · how to join sheet metal

5 · flange making machine

6 · flange forming machine

7 · countersunk lap seam

The timeless elegance of a bright white house color alongside a gray roof cannot be overstated. White offers a clean, crisp contrast to the subtle sophistication of gray, creating a classic look that never goes out of style.

Learn how to design flanges for sheet metal fabrication with a simple formula that guarantees the right height and bend radius. Avoid .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Sheet metal flanges offer strength, versatility, and ease of assembly. They improve the reliability and functionality of sheet metal components by providing structural support, sealing surfaces, and mounting surfaces.Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets .

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Sheet metal stretches when it bends. It can crack instead of stretch depending upon several variables, including the tooling applied and the direction of the micrograin of the material. Unless dedicated tooling is used, the inside .

Making the Miter Flange. In the CAD shop, a miter flange is a time-saving miracle. A simple sketch can create one (see Figure 4a) or more bends (see Figure 4b) on one or more edges in a single modeling step. When more .Curling – A forming process which leaves a circular, closed loop at the end of the sheet. This forms a safe edge for handling and stiffens the part’s edge. Flange Length – The length of the workpiece when measured from the apex to the .BILITOOLS 3-Piece Hand Seamers Sheet Metal Tools, Sheet metal Bending Pliers Set Straight, 45° & 90° Metal Bender Tool 4.4 out of 5 stars 264 1 offer from 99 $ 66 99 Sheet metal forming involves the deformation of sheet metal blanks with the help of die and tool sets by application of . Sheet metal forming is one of the major forms of forming technologies [1,2]. . stretch, shrink and hole .

The flange tool makes it easier to punch in the numbers for what you are trying to do, then solidworks uses your bend data to generate the flat to match. If you are using a pre-determined flat and are trying to get a specific flange .Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of theUnfailing Performance & Desired Results – Punch and Flange Tools. Since its inception, Woodward Fab has been providing innovative sheet metal fabrication tools to make fabrication tasks easy and quick. Amongst our products, punch and flange tools are extremely popular as they are handy, easy to use, and durable. Sheet metal forming processes include processes such as deep drawing, shearing, blanking, punching, piercing, trimming, drawing, bending, flanging and coining, embossing, flanging and hemming processes. . [13], [14], [15] extensively studied the stretch flange forming process and utilized aluminum alloy 5052 as workpiece material in majority .

The transverse duct flange forming machine presses galvanized sheet metal to form ducts and flanges in one piece, thus the final product is a transverse duct flange. Our machines have higher productivity, produce less material waste, small duct leakage, and low energy consumption thus saving production cost.

types of sheet metal joints

tdf flange forming machine

An edge flanging machine is a specialized tool used to create a flange or lip along the edge of a sheet metal workpiece. Flanges are commonly used for various purposes, including: Reinforcing the edge of the workpiece: A flange can provide additional strength and support to the edge of the sheet metal, preventing it from bending or warping.Sheet Metal Fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. . Flange length must be at least 4 times the material thickness. Rule of thumb It is recommended to use the same radii across all bends, and flange length must be at least 4 times the material thickness. .

Flange forming is a process which is wide spread in macro range for blanks with thicknesses from less than 1 mm up to several millimeters. Flange formed geometries are used as preforms for threads but also as device to give guidance and contact face to bolts and axles in sheet metal. A great advantage of flange forming compared to other machining processes is .

Success Sheet Metal Works - Forming Machine, Air Duct & Metal Sheet Bending Machine Manufacturer from Mumbai, Maharashtra, India . S uccess S heet M etal W orks. . Tdf Flange Forming Machine. Sheet Bender. Duct Flange Corners . Call 07942540349 77% Response Rate . Send E-mail. About S uccess S heet M .The raw and flange corner joint is a type of sheet metal joint that closely resembles a plain lap joint and involves a flat stock piece joined to a 90-degree bend to form the corner. . Creating a flange joint involves forming a flange on each piece and then placing one on top of the other, with both types being formed in a similar fashion. .Automatic Angle Flange Forming Machine The machine will automatically form steel sheet metal into an angle flange and cut it according to the exact dimensions.; Flange Drilling Machine The flange drilling machine creates holes for screws to hold each duct component together. The maximum workable material thickness is 5mm. Transverse Duct Connector Flange Forming .

Sheet Metal Punch and Flange Tools; S&G Tool 91625; S&G Tool Aid Pneumatic Panel Crimpers 91625. 3.5 out of 5 stars . Can be used on up to 16-18 gauge sheet metal, depending on the air hammer used and operating air pressure. . S & G Tool Aid pneumatic panel crimpers will patch sheet metal panels uniformly and quickly by forming a step .Formulas: Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length. Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern. . / Sheet Metal Forming Machinery / By Harry Thompson IV / July 12, 2021 . Manual versions of the Flanger and Rotary Machines: Lockformer Easy Edger (left) and Pexto 622 Rotary Machine (right) . Empire Power Rotary .

INCLUDES OFFSET DIES to create channels, flanges and a multitude of profiles. This Gear-Driven Bead Roller Delivers Maximum Forming Power While Requiring Minimal Handle Force; A Generous 19” Throat Depth Provides The Ability To .Amazon.com: sheet metal edge roller. . Metal Ball Belt Set of 6 Dies,Bead Roller Kit,Generous 12 inch Throat Industrial Cast-Iron Metal Beads Roller,18 Gauge Sheet Metal Rotary Forming Machine. 3.9 out of 5 stars. 77. 9.99 $ 169. 99. List: 9.99 9.99. 11% off coupon applied Save 11% with coupon.Sheet Metal Machines; Flange Forming Machinery; Auxiliary Machinery; Company Information. About Us; Cases; Service; Solution; Contact Us +86-510-86065300 +86-510-86065200. [email protected] +86-13771263230. Home Machines Solution About Us Cases Service Videos Contact Us.

This sheet metal corner forming machine can be used to bend a wide variety of materials including mild steel, stainless steel, aluminum, etc. with no size limitations. . The new tooling design allows former corners in any flange height in connection with any material thickness up to 5 mm. The former corner radius can be determined from 2 mm . Making the Miter Flange. In the CAD shop, a miter flange is a time-saving miracle. A simple sketch can create one . As represented in Figure 7b, the Forming Tool model is drag-dropped from its folder onto a face of the sheet metal part. The Forming Tool model may be located and rotated for precise positioning.TDC Flange forming machine T20 air metal duct sheet flange forming machine for sale. ,200.00-,800.00. Min. Order: 1 set. Previous slide Next slide. Factory price galvanized sheet metal air duct tdf flange roll forming machine for ventilation industry. Ready to Ship. ,000.00-,500.00.Wrinkling in flange and cup wall: This is like ups and downs or waviness that is developed on the flange. If the flange is drawn . Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change.

SHEET METAL FORMING-PRESSING-01 0 2 03 0 4 Ke yw ord K e y w o r d K e y w o r d Ke yw ord Introduction dan Definisi Bending Pressing METAL FORMING Rolling. INTRODUCTION DAN DEFINISI (1) . - Flange - Curling - Burring - Stamp PRESSING-PROSES PEMBENTUKAN-Break Time 15 Minutes Lorem ipsum dolor sit amet, consectetur

Flange Machine: Sheet metal forming refers to a broad set of manufacturing processes used to convert flat metal sheets into desired shapes and geometries. It is an essential part of the metalworking industry, widely used in the automotive, aerospace, construction, and electronics industries. This process involves applying force to deform the .Find your sheet metal flanger, sheet metal slitter, and more at Rams Equipment. Check out our official website today for more information. . This unit is designed for forming a 7/32" right angle flange, for both inside and outside radiuses. This unit can also be used on duct elbows as well.Premier choice for bending, folding, flattening and straightening sheet metal edges or safely gripping and moving sheet metal. 3inch jaw width. Drop-forged, high-impact jaws feature depth markings graduated in 1/4 In. Easily bend flanges or completely flatten seams from 1/4 to 1-1/4 In deep in 24 gauge galvanized or mild steel. Made in the USA

sheet metal joining methods

metal outdoor house decor

$14.99

sheet metal flange forming|countersunk lap seam