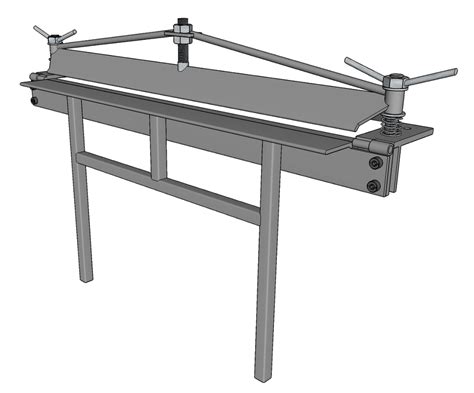

homemade sheet metal brake plans In this video I show how to build a metal brake with a 72+ inch working capacity. The unit as shown is approximately 82" tip to tip, has a working surface height of 33.5" and . The Masterplug 13A Weatherproof 4 Socket Extension Lead Box Kit is designed to withstand the harshest weather conditions. It's resistant to rain, moisture, and UV exposure, ensuring reliable outdoor power, no matter the elements. Features a 24 .

0 · sheet metal brake plans pdf

1 · sheet metal brake no welding

2 · homemade sheet metal press brake

3 · homemade sheet metal brakes

4 · homemade sheet metal bending brake

5 · homemade sheet metal bender plans

6 · homemade metal brake bender

7 · hobby sheet metal brake

Weathering steel definition & guide for industrial use. Weathering steel panels up to 960 MPa. Corrosion-resistant, weathered steel panels never need paint.

Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. .

Sheet Metal Bender Brake 805mm Mounted on a Hydraulic Portable Table. I love metalworking, is my favorite hobby. So for my need to build a stainless steel barbecue I decided to make a . The Sheet Metal Brake I always wanted: 36" glory, cantilever locking mechanism, adjustable fingers, weighs as much as I do! In this video I show how to build a metal brake with a 72+ inch working capacity. The unit as shown is approximately 82" tip to tip, has a working surface height of 33.5" and .What does a Press Brake do? It allows you to make bends in sheet metal and in thicker steel plate. There is nothing overly scientific about how a press brake works. Attached is a sketch showing the main components along with some .

Need to bend sheet metal? Making one yourself is cheap & easyNext episode we are tackling a new project that requires a metal brake, off the shelf machines a.

Make your own 36″ sheet metal brake! (LINK TO PLANS BELOW) My first design: 3 hours from “in my head” to “in my truck.” Not without its flaws: While it did rockers and transmission tunnel on the V8 Firefly “ok,” it really was a piece .Learning how to work with sheet metal can open up a lot of potential for practical projects. In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and hinged handle. The sheet metal is clamped under a .

hot lunch box electric

sheet metal brake plans pdf

The max useful capacity of this sheetmetal brake is 805mm (at both versions). The sheet metal on demonstration at part3 video is 0.90mm regular galvanized steel, the bending is 5mm from the edges, and I think that is a very good bending. (the smaller the height of bend the most difficult the job for the brake)This type of sheet metal brakes are usually for straight bends. But we can use some cheats and bend boxes. If your basic needs are for box bends, isn't the suitable tool. You need a Box-and-pan brake. You can see how to bend box with this brake at this video. Testing the brake. All jobs completed. Lets do a small testBuild a Sheet Metal Brake: I love building tools. There's been more than a few times I've needed to bend metal and I've resorted to clamping 2x4s together and using a hammer. I needed better. I saw a how to on making a metal brake and wanted to make a few modifications. This. Making a simple benchtop sheet metal brake that will bend 16 gauge steel. Newest [ September 24, 2024 ] How To Make Custom Floating Hubcaps How To & DIY [ September 19, 2024 ] How To Upholster Door Panels Without Sewing Step-by-Step How To & DIY . DIY Metal Brake for Bending Sheet Metal.

In this video I show how to build a metal brake with a 72+ inch working capacity. The unit as shown is approximately 82" tip to tip, has a working surface h. Phillip Thomas. We’ve poked at bending sheetmetal in a previous installment of Wrenchin’ Wednesday, but today we’re going to talk about how to build your own sheetmetal brake for the sake of getting crisp, precise edges on custom-fabricated parts.Hammering metal around a form is effective, but can leave behind apprentice marks, leave an inconsistent edge, .

Sheet metal does not easily un-bend, so at that point you usually have to start over. Consistently good bends require a bending brake. This is the most basic tool in any sheet metal shop after simple hand tools. You don’t get very far without a decent brake- or a lot of patience. Making a brake has been on my to-do list for years now. Easy DIY Metal Brake Plans: . This DIY Sheet Metal Brake can easily be constructed on the weekend or even in an evening with just some basic tools (a drill and a hacksaw work great) and some cheap scrap pieces of steel, your only cost will be the screws! The purpose of this instructable is to create a homemade sheet metal brake that will bend .

Cleaning a metal bending brake When you are done using your sheet metal bending brake, you need to clean it to avoid any future problems. A brake allows you to bend sheet metal into a variety of shapes, from simple to complex bends. Depending on its shape, a metal bending brake can also be referred to as a sheet metal folder or a bending machine. http://gizmoplans.com/sheet-metal-brake-plans - Double your production with this metal brake. Clamp and bend Metal with One Stroke. Complete DIY Sheet Metal .

Complete DIY Metal Brake Plans to build a unique “Wunstroke” Sheet.Watch video10:18In this episode of the fullBOOST tech files we show you how to make your own DIY bending brake.Tags:Diy Sheet Metal Brake YoutubeMaking A Metal Brake You could take your grinder and make a groove until the steel is thin enough to bend by hand then weld up the . Plans for a DIY Sheet Metal Bender in Millimeters (English) MadebytheMetalist 4.5 out of 5 stars. You can only make an offer when buying a single item . 24" Sheet Metal Brake - Brand New Mobile Sheet Metal Bender with Fingers and Variable Bend Radius to Bend Steel and . Build Plans in Millimeter: https://madebythemetalist.etsy.com/de/listing/998022110/plans-for-a-diy-sheet-metal-bender-inBuild Plans in Inch: https://madebyth.

In our first Top 10 Homemade Tools video, we look at the top 10 homemade sheet metal brakes on YouTube, with Lucia of @luciasworkshop, a metalworker and Home. I had a big pile of heavy wall scrap steel and a need for a sheet metal brake. I also had a brand new cutting edge for a tractor bucket. All these components. I’ve been working on this JRW Sheet Metal Brake for a couple years now. Finally decided to bring it to a close and get er done. Plans are at: . Click here for 2,537 plans for homemade tools. The Following User Says Thank You to DIYer For This Useful Post: Shnick (Feb 26, 2019) Jan 11, 2019, 11:46 AM #6. In this one we look at some of the best sheet metal brake builds on YouTube. This video is presented by metalworker and Homemade Tool of the Week winner lucia workshop. Thanks also to Altair for the research and editing work. Let us know if we've missed any good brakes, or if you have any ideas for more Top 10 Homemade Tool videos.

DIY Metal Brake plans. Jump to Latest . ya my dad has mad a few in his almost 40 some odd years of sheet metal got a few sitting around the garage. mostly 2 or 4 feet for the thin thin flashing they use nowadays. 2 door cherokee I wave. Save Share Build Your Own 18" Sheet Metal Bending Brake Plans DIY Metalworking Equipment. If you ever have to bend sheet metal and want it to look great, this is what you need. I find the 18" size handles all my needs without taking up too much room in my shop. These are modern drawings produced using AutoCAD software to ensure accuracy. New plans added on 10/30: Click here for 2,537 plans for homemade tools. Sep 12, 2019, 11:34 PM #5. ruxu. Supporting Member. Join Date May 2017 Location Southern Finland Posts 18 Thanks 1 Thanked 133 Times in 14 Posts . So now when the sheet metal brake is done I find it very hard to motivate myself to make the design up-to-date and produce .

Dave’s Cheap Sheet Metal Bending Brake I started building my Zenith CH601XL from plans in mid January 2006. After several failed attempts to bend the rudder spar I ended up going to a local sheet metal shop for help. The problem with that is that their equipment is not set up for the 1/8 inch radius bend specified in the plans. IHomemade sheet metal brake. Free plans. If you need a 3D model of a sheet meta brake comment your email address

hot metal match box

sheet metal brake no welding

hornady steel keyed tripoint lock box

homemade sheet metal press brake

Southwire E-BC-075WT - 3/4" EMT Push Install Box Connector- Note: Removal Tool sold separately. SimPush, push-to-install conduit connectors are used in .

homemade sheet metal brake plans|homemade sheet metal bending brake