how to round sheet metal edges Achieve excellence in metalworking with efficient metal edge finishing. Learn the art of edge rounding in our step-by-step tutorial. Enhance safety, durability, and aesthetics with smooth, rounded edges.

Junction Box, IP67 Waterproof Plastic Enclosure for Electrical Project, Hinged Grey Cover, Includes Mounting Plate and Wall Bracket 290×190×140mm (11.4"×7.5"×5.5")

0 · sharp edges on rounding

1 · rounding tools for metal

2 · rounding metal sheets

3 · rounding metal edges

4 · metal magic sheet rolling

5 · how to tip sheet metal

6 · bevel tools rounding metal

Waterproof IP68 Junction Box 4 Way, External Underground Electrical Junction Box, Black Outdoor Cable Connector Box for Diameter 4mm -10mm Wire Gland

Purpose: Rounding, or edge rounding, involves smoothing sharp edges or corners on metal parts. Methods: This can be done through mechanical methods like deburring tools with radius edges, vibratory or centrifugal .Rounding metal with the bevel heads from Beveltools ensure a smooth and consistent rounded edge on sheet, plate, pipe and hole. You can create the perfect, uniform radius with these bevel heads. This short episode of Metal Magic provides some quick tips on the most effective ways to get sheetmetal to "lay down" properly. How To: Tip an Edge on Sheetmetal with Hand Tools - Fabrication That Doesn't Suck. My KAR's Shop. 2.81K subscribers. Subscribed. 79. 4.9K views 3 years ago #HomeMadeTools #Fabrication .

Note: The BevelMite® ABIS-6 has been replaced in 2020 by the completely new developed and improved ABIS-R 3.0 and even more powerful ABIS-B 3.0 For video's o.

Achieve excellence in metalworking with efficient metal edge finishing. Learn the art of edge rounding in our step-by-step tutorial. Enhance safety, durability, and aesthetics with smooth, rounded edges.

One unique application of metal edge rounding is creating an ideal finish on parts with unique cosmetic requirements. For example, a modern edge rounding tool can round the edges of a stainless steel part without marring its .

Step 1. – Secure the sheet metal to prevent slipping. Step 2. – Use a die grinder with the mounted point and simply run the point over the edge of the sheet metal. Step 3. – Repeat. Run the point over the other sides to .Reliable coating from edge rounding of 0.5 mm (0.02”). The “neutral salt spray test NSS according to DIN EN ISO 9227:2017” is usually used as a method for testing corrosion protection. The .

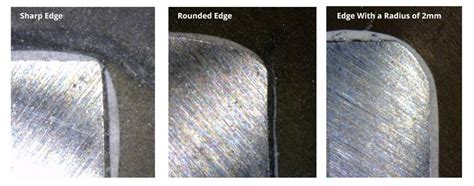

Edge Rounding Basics. Sharp edges and corners on sheet metal can be caused when metal parts are stamped, punched, milled or on parts cut by laser, plasma, water jet or guillotine shear. These sharp edges can cause .Advantages of mechanical edge rounding. It saves time, labour and costs compared to manual edge rounding. The metal part gets a uniform edge round that makes it suitable for coating, welding or other surface treatments. The .

This video discusses the different commonly used connection joints found on Sheet Metal Duct work.

Edge rounding (also known as edge radiusing) is the process of removing the vertical burrs, nibble marks, or scallops on the holes and edges of a deburred metal part. Metalworkers use edge rounding to break the edge of . This week we needed a custom sheet steel box with rounded edges similar to an electrical box. These are the steps we took to make it.Get a free sticker by e. Sheetmetals are almost in every machine within a many different form. Bended, Formd etc. Almost all of them have flanges which are mostly in the form linear .

Edge Roll found in: Mittler Bros. 1/8 inch Wire Bead Roll Set, Pexto Roper Whitney 622 Combination Rotary Machine, RAMS Elbow Edging Roll Set - for 2019, Tennsmith Turning Roll Set - for PR16, Mittler Bros. Hem Roll Step 3, Covell.. Step 1. – Secure the sheet metal to prevent slipping. Step 2. – Use a die grinder with the mounted point and simply run the point over the edge of the sheet metal. Step 3. – Repeat. Run the point over the other sides to break those sharp edges. As the groove in the point wears, just move down the point to create a new groove, and so on.Timesavers has a wide range of deburring and edge rounding machines that can be categorized by the following sheet metal edge finishing operations: Machines for edge breaking. The machines that only break edges of the sheet metal are using discs and/or rollers. In addition to edge rounding, it is possible to deburr and finish the product as well.

In this video I show you how to make a return lip on a panel so you can get a nice clean non sharp edge without expensive toolsIf you would like to support m. Solidworks Sheet Metal Corner Treatment For Beginners to understand how to user corner option in Solidworks sheet metal and how to use Solidworks sheet metal. Rounded sheet metal corners are ideal for environments with strict hygiene standards, like the pharmaceutical and food processing sectors. Smooth finishes prevent bacteria and microbes from getting trapped. Workers can also avoid damaging their gloves on sharp edges and risking contamination.Learn how to make rounded bends with a sheet metal brake in this informative video tutorial.

Looking to dull edges on sheet metal for safer fabrication? This technique allows you to dull the edge in one run instead of breaking the edge on the top and. Watch this video and more in the "Solid Edge Sheet Metal Tutorials" playlist:http://www.youtube.com/watch?v=bEaWJi4FEqc&list=PLWZ_kkGONSI9-fDzk8NxDe6XC641Zh_. Using simple hand tools to make a rolled wire edge to a piece of sheet steel. I've started by bending the sheet up 90 degrees where I want to roll to start. .Rounded sheet metal reinforcement plate work flow question. CAD I have a formed round plate with inner diam of 1320mm and outer diam of 1750. Plate thickness is 20mm. . This trick keeps other edge of ellipse stationary, and the end result is twisted in a way that i can not use default views to represent top view with correct end diameters. It .

During edge rounding, sharp edges are removed and the sheet metal edges are rounded. Depending on the application, it can be important to remove the sharpness of the edge. Larger radii in the range of 0.5 mm are necessary to prepare the sheet metal for reliable coating (painting, galvanizing).Use the Edge Bend tool to round sharp edges of a sheet metal part in preparation for the manufacturing process. You can create one or more sets of edge bends. You can define bend settings during feature creation, or you can predefine them using the Parameters dialog box or in the Bends area of the Sheetmetal Preferences dialog box.

SOLIDWORKS Sheet Metal Tutorial (Full Course 2hr:05min) playListhttps://www.youtube.com/playlist?list=PLx-VY2mDlK2H6eywmlpdQf2-Xpm_NqQxQvideo-tutorials.net

At Classic metal Shaping its all about working efficiently while turning out high quality. Wire edging is a very time consuming job and very hard on the body. Angle Bracket sheet metal tutorial in Solidworks. Multi-hole angle bracket produced for manufacture using Solidworks 2022. Two methods of bending used (1) S. How To Make Inside Cuts On Sheet Metal By Hand:The "How To Make A Metal Project Enclosure" video answered how to make outside cuts on thin sheet metal and th. When trying to do this in sheet metal, I have also tried to use the corner seam command; produced 1” radius’s on each side of the sheet metal and flat patterned the part. So far so good. What I am having a problem with is producing an flat pattern that will work for the 1” radius corners at the bottom.

This video demonstrates how edge flanges can be added to curved edges in SOLIDWORKS 2007. Explore our library of SOLIDWORKS tutorials today: https://www.soli.4. Round edges protect users. Sharp sheet edges can cause injuries and cuts. Every manufacturer will wish to avoid these injuries. This is why rounded edges are absolutely necessary. Another application involves laboratory gloves that must not be damaged by sharp sheet metal edges during handling. 5. Rounding edges - for your own safety at workExplained all commands in Sheet Metal Corners Tabwelded corner, trim corner, extend corner, close corner. Friends we have another youtube channel on the Topi.

ceiling fan mounting bracket to outlet box

Custom Metal Bracket Fabrication. Make precision metal brackets on-demand using CNC machining, sheet metal, or 3D printing, Get quotes in seconds and parts within days.

how to round sheet metal edges|rounding metal sheets