cnc machine for rapid prototyping Inconel. This 3D-printed metal is a nickel chromium superalloy ideal for rocket . Additive manufacturing is the process of creating an object by building it one layer at a time. It is the opposite of subtractive manufacturing, in which an object is created by cutting away at a solid block of material until the final product is complete.

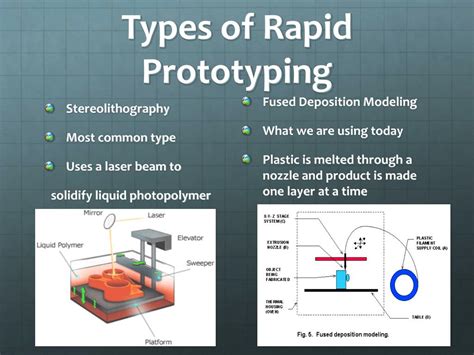

0 · types of rapid prototyping methods

1 · types of rapid prototyping machines

2 · rapid prototyping services near me

3 · rapid prototyping pros and cons

4 · rapid prototyping companies near me

5 · rapid prototyping companies in usa

6 · rapid prototyping cnc machining

7 · cnc machining rapid prototype manufacturer

CNC machines, or Computer Numerical Control machines, are manufacturing marvels that integrate accuracy, speed, and regularity based on computerized systems. The machinery is used across different sectors, such as aerospace and automotive, for making intricate components that are of high quality.

CNC Machining. Leverage the same speed, precision, and reliability in machining that you’re accustomed to at Protolabs but unlock advanced machining capabilities like tighter tolerances and volume pricing through our manufacturing network. Learn MoreCareers - Protolabs | Rapid Prototyping & On-demand Production ServicesThis white paper examines various digital manufacturing options available to .The world's leading medical device development companies turn to .

Inconel. This 3D-printed metal is a nickel chromium superalloy ideal for rocket .

Mitigate design risk through rapid iteration and prototyping in production materials .

Consumer Electronics - Protolabs | Rapid Prototyping & On-demand Production .

Coated Parts in as Fast as 4 days! Get machined parts anodized and chromate .Robotics is a diverse, relatively new industry, but most prominent in the .

CNC rapid prototyping is a subtractive manufacturing process that uses computer numerical control (CNC) machine tools to create physical prototypes or product models. The machine tool is controlled by a computer .CNC Machining. Leverage the same speed, precision, and reliability in machining that you’re accustomed to at Protolabs but unlock advanced machining capabilities like tighter tolerances and volume pricing through our manufacturing network. Learn More

CNC rapid prototyping is a subtractive manufacturing process that uses computer numerical control (CNC) machine tools to create physical prototypes or product models. The machine tool is controlled by a computer program so that the cutter automatically cuts metal and plastic materials to obtain the desired shape.

3ERP is one of the most reliable rapid prototyping companies. We can turn your designs and ideas into real parts in just a few days. By using CNC milling & turning, we can make a wide range of prototypes and production parts. We offer low-volume prototype moldings and .Understanding the requirements of your own products will help define what machine is the best fit for your prototype lab. Define what materials you’ll be working with, what dimensional tolerances you need to hold, and what sort of geometric features you need to create.We transform your ideas into precise, real prototypes, accelerating product development with technologies like 3D printing, CNC machining, and injection molding. Our approach enables rapid testing and validation of parts, smoothing the path from concept to market.

With the neo, you can design, mill, test, revise, and repeat in a day vs. waiting weeks for outsourcing. See the machine in action here. Spindle speeds up to 40,000 RPM. Uses less energy than a standard hand-held hair dryer. CAM Assistant walks .Speed and efficiency: CNC machines offer rapid production times, critical for prototyping. Lead times on the MakerVerse platform start at just six days. Cost-effectiveness: CNC machining is cost-effective for low-volume production and prototypes, particularly compared to other manufacturing processes like injection molding, which requires .Rapid Prototyping. Rapid Axis’s CNC machines are great for prototype manufacturing. Since the machine runs quickly and creates highly accurate parts, you can have a functional prototype created in days. CNC machines tend to make pieces in production-grade metals or plastics, so the prototype you get will be fully operational.

Turn Ideas into Prototype Parts with CNC Machining. As Low As $ 24.89. Instant Quote within Minutes; Rapid Prototyping in 2 Days Flexible Low-volume Manufacturing . Rapid Prototyping and Mass Production Parts High Quality Injection Moulding and Parts. From .CNC prototype machining enables the rapid production of parts and ensures accuracy and consistency. Producers can create high-quality components, especially in industries where effective prototyping is critical.CNC Machining. Leverage the same speed, precision, and reliability in machining that you’re accustomed to at Protolabs but unlock advanced machining capabilities like tighter tolerances and volume pricing through our manufacturing network. Learn More CNC rapid prototyping is a subtractive manufacturing process that uses computer numerical control (CNC) machine tools to create physical prototypes or product models. The machine tool is controlled by a computer program so that the cutter automatically cuts metal and plastic materials to obtain the desired shape.

3ERP is one of the most reliable rapid prototyping companies. We can turn your designs and ideas into real parts in just a few days. By using CNC milling & turning, we can make a wide range of prototypes and production parts. We offer low-volume prototype moldings and .Understanding the requirements of your own products will help define what machine is the best fit for your prototype lab. Define what materials you’ll be working with, what dimensional tolerances you need to hold, and what sort of geometric features you need to create.We transform your ideas into precise, real prototypes, accelerating product development with technologies like 3D printing, CNC machining, and injection molding. Our approach enables rapid testing and validation of parts, smoothing the path from concept to market.With the neo, you can design, mill, test, revise, and repeat in a day vs. waiting weeks for outsourcing. See the machine in action here. Spindle speeds up to 40,000 RPM. Uses less energy than a standard hand-held hair dryer. CAM Assistant walks .

Speed and efficiency: CNC machines offer rapid production times, critical for prototyping. Lead times on the MakerVerse platform start at just six days. Cost-effectiveness: CNC machining is cost-effective for low-volume production and prototypes, particularly compared to other manufacturing processes like injection molding, which requires .Rapid Prototyping. Rapid Axis’s CNC machines are great for prototype manufacturing. Since the machine runs quickly and creates highly accurate parts, you can have a functional prototype created in days. CNC machines tend to make pieces in production-grade metals or plastics, so the prototype you get will be fully operational.

Turn Ideas into Prototype Parts with CNC Machining. As Low As $ 24.89. Instant Quote within Minutes; Rapid Prototyping in 2 Days Flexible Low-volume Manufacturing . Rapid Prototyping and Mass Production Parts High Quality Injection Moulding and Parts. From .

fireproof steel cabinet suppliers

CNC milling is a manufacturing process that uses a cutting tool mounted on a rotating spindle to selectively remove material from a block of raw substrate. The workpiece is rigidly mounted to a table, and this table moves or rotates on different planes so the tool can work at many angles.

cnc machine for rapid prototyping|types of rapid prototyping methods