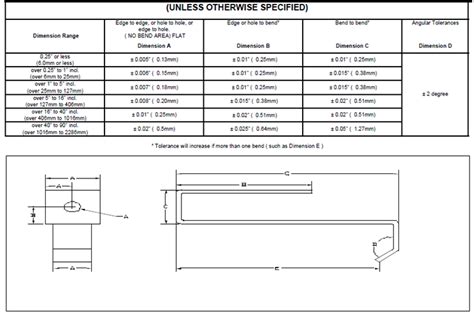

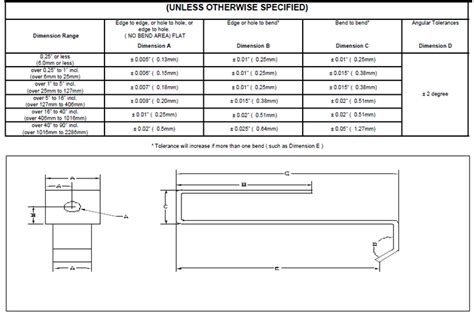

bending tolerance for sheet metal Sheet Metal Tolerances for Bending and Stamping. Both bending and stamping have their unique tolerances. Bending: Bending is the process of reshaping metal without removing material. . RSC Precision Engineering offer CNC precision machining service for the pharmaceutical, medical and surgical instrument sector. We are precision engineers with the expertise and .

0 · standard sheet metal tolerances chart

1 · sheet metal tolerance chart

2 · sheet metal thickness tolerance standard

3 · sheet metal bending tolerance standard

4 · sheet metal bending guide pdf

5 · sheet metal bend tolerance chart

6 · sheet metal bend relief guidelines

7 · maximum thickness sheet metal bending

$59.00

standard sheet metal tolerances chart

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication.Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the .

Sheet Metal Tolerances for Bending and Stamping. Both bending and stamping have their unique tolerances. Bending: Bending is the process of reshaping metal without removing material. .

real steel world robot box

Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The looser tolerances achieved by the sheet metal method are . We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. Standard press brake tooling requires that any feature be 3 . Sheet metal tolerances are the maximum allowable dimension deviation during sheet metal fabrication. This concept is crucial as it directly influences the product’s quality and . Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from .

They need to know what the sheet metal tolerance variables are and how to compensate for them, especially when single-piece jobs or small batches require operators to achieve the correct bend angles and dimensions . For sheet metal manufacturing, tolerances typically range from ±0.005″ to ±0.060”. The total permissible variation (upper and lower) in a dimension is known as tolerance zone. .

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication.Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the holdable tolerances could be for usual shop floor operations. The bending (forming) process is a non-material-removal process.

Sheet Metal Tolerances for Bending and Stamping. Both bending and stamping have their unique tolerances. Bending: Bending is the process of reshaping metal without removing material. Tolerances are affected by the type and properties of the bending machine. We have calibrated our modern bending machines for consistent bending angles. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The looser tolerances achieved by the sheet metal method are a product of the highly variable processes used to achieve a geometry. Imagine bending sheet metal without leaving a single mark or scratch. In this article, we explore innovative techniques for mark-free sheet metal bending, addressing challenges like friction, material hardness, and. We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. Standard press brake tooling requires that any feature be 3-4x the material thickness away .

Sheet metal tolerances are the maximum allowable dimension deviation during sheet metal fabrication. This concept is crucial as it directly influences the product’s quality and performance. Ensuring every product falls within this tolerance range in our work is essential. Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from dimensional deviations to angular tolerances.

They need to know what the sheet metal tolerance variables are and how to compensate for them, especially when single-piece jobs or small batches require operators to achieve the correct bend angles and dimensions on the first try.

For sheet metal manufacturing, tolerances typically range from ±0.005″ to ±0.060”. The total permissible variation (upper and lower) in a dimension is known as tolerance zone. Tighter tolerances yield more precise parts but increase production costs. while looser tolerances are economical but may cause alignment issues.

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication.Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the holdable tolerances could be for usual shop floor operations. The bending (forming) process is a non-material-removal process.Sheet Metal Tolerances for Bending and Stamping. Both bending and stamping have their unique tolerances. Bending: Bending is the process of reshaping metal without removing material. Tolerances are affected by the type and properties of the bending machine. We have calibrated our modern bending machines for consistent bending angles. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The looser tolerances achieved by the sheet metal method are a product of the highly variable processes used to achieve a geometry.

Imagine bending sheet metal without leaving a single mark or scratch. In this article, we explore innovative techniques for mark-free sheet metal bending, addressing challenges like friction, material hardness, and. We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. Standard press brake tooling requires that any feature be 3-4x the material thickness away . Sheet metal tolerances are the maximum allowable dimension deviation during sheet metal fabrication. This concept is crucial as it directly influences the product’s quality and performance. Ensuring every product falls within this tolerance range in our work is essential.

Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from dimensional deviations to angular tolerances. They need to know what the sheet metal tolerance variables are and how to compensate for them, especially when single-piece jobs or small batches require operators to achieve the correct bend angles and dimensions on the first try.

real steel boxing ring

The Box Plot, sometimes also called "box and whiskers plot", combines the minimum and maximum values (i.e. the range) with the quartiles into on useful graph. It consists of a horizontal line, drawn according to scale, from the minimum to the maximum data value, and a box drawn from the lower to upper quartile with a vertical line marking the .

bending tolerance for sheet metal|sheet metal bending guide pdf