how to do sheet metal in solidworks How to Use SolidWorks Base Flange | SolidWorks SheetMetal Tutorial #1. Base Flange is first and basic step used to start sheet metal model. It is applicable one per part file. . Designed for a variety of applications and environments, our catalog of electronics .

0 · solidworks sheet metal tutorial pdf

1 · solidworks sheet metal template

2 · solidworks sheet metal practice exercises

3 · solidworks sheet metal pdf

4 · solidworks sheet metal guide

5 · solidworks sheet metal examples

6 · sheet metal solidworks tutorial

7 · sheet metal modeling in solidworks

Outdoor Electrical Box, Waterproof Electrical Junction Box IP65 ABS Plastic Enclosure with Fan & Thermostat, Mounting Plate and Hinged Lid (15.7" H x 11" L x 5.9" W)

solidworks sheet metal tutorial pdf

To start, open a new Part document in Solidworks. The Sheet Metal tab is only accessible in Part mode. You can not create Sheet Metal . See moreThere are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the Edge . See moreCongratulations. You have made a bracket using the sheet metal features in Solidworks. In future articles, we will look at the more advanced sheet metal features, and we will . See more

How to Use SolidWorks Base Flange | SolidWorks SheetMetal Tutorial #1. Base Flange is first and basic step used to start sheet metal model. It is applicable one per part file. .

solidworks sheet metal template

solidworks sheet metal practice exercises

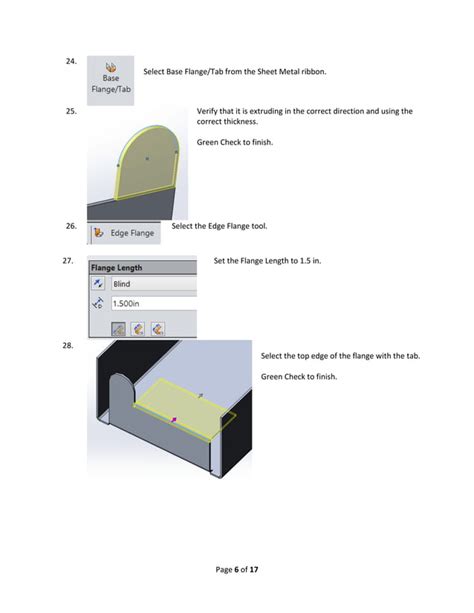

By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •.You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, . In this lesson, you create the sheet metal part. This lesson demonstrates: 1.Creating a base flange 2.Adding a miter flange 3.Mirroring the part and creating.

Learn how to create a sheet metal workpiece and learn how to create Flat pattern on SOLIDWORKS software.

SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create .You can add edge flanges to one or more edges. A miter flange feature adds a series of flanges to one or more edges of a sheet metal part. You can create compound bends in sheet metal .Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an .

Breakout Session: Sheet Metal Tips and Tricks. See more at: http://www.goengineer.com/products/solidworks/Learn how to get started with SOLIDWORKS Sheet Metal. See more at: http://www.goengineer.com/products/solidworks/Learn how to get started with SOLIDWORKS Sheet Metal. Whether you have just started using .

illinois iron inc architectural metals rails fences custom fabrication

What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property.

SolidWorks Sheet Metal Tutorial for Beginners ~ Shows how to make a simple sheet metal part and then Save-As a .DXF file to send to the Metal Cutting CNC Las.In another video you may want to dive deeper into why it's important. SW is a great piece of software but I feel it lacks features when it comes to sheet metal fabrication. There have been countless times I've received 3d model files from engineers and I can almost instantly tell if they are using SW and don't have much sheet metal experience.I do a lot of sheet metal design and honestly find the tool to be extremely limiting. I’d rather just create a global thickness variable and model the geo natively as nature intended rather than spend my time finding creative ways to work around the limitations of the sheet metal cad tools.Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model.

If you use the sheet metal tools in Solidworks (or most other CAD software), some of the cuts and notches are generated kind of automatically when you bend a side, etc. . i worked on one startup job where we contracted with a local sheet metal fab shop to do our sheet metal. we provided dimensioned drawings of the flat pattern for them. in this tutorial video we will learn how to sketch sheet metal drawings in Solidworks with the help of sheet metal tools.Please subscribe our channel for mor.

I've been told to avoid "Convert to Sheet Metal" and "Insert Bends" (just tips for good practice), but I'm not very familiar with SolidWorks yet and I don't know how to do a revolution using the Sheet Metal parts. So, I've run into the problem of using "Convert to Sheet Metal", but only getting a little bit of it to convert: So any help would .I inherited a design from someone else, who originally modeled a part as sheet metal. At some point, for whatever reason, he added thickness to represent a thick metal plate. All was fine until I needed to add a cut partway through the thickness. This doesn't work in sheet metal. I tried the obvious things, like deleting the sheet metal feature.Looking to try SOLIDWORKS today? Access a free 7-day online trial that performs brilliantly on any computer with a steady internet connection.U.K. & Ireland .

Sheet Metal Design in SolidWorks for Beginners | Step-by-Step TutorialIn this comprehensive SolidWorks tutorial, we'll walk you through the fundamentals of s.

Do you guys do that or do you create an assembly and pretend the parts are welded, when dealing with sheet metal parts. My current application involves a large sheet metal part with many bends accompanied by small welded plates for stronger tap locations. My main concerns are in the ease and flow of creating drawings and allowing my sheet metal .

I'm trying to convert a loft into a sheet metal part to be flattened. The part is attached below. Any suggestions? Thought about exporting to a STEP and then bringing it back in but no luck unless I'm missing a step. The project is for a mixer blade. I used loft because I know the beginning and ending location of the part on each plain. Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it can be c.

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. . #sheetmetal Sheet Metal Design Sheet Metal FabricationSheet Metal Do you want to become an expert of Modeling on SolidWorks, then this video exactly for you..Looks good brother! One thing I'd note as someone in the metals industry is to take caution when putting holes or other features very close to bends (like the hole in the corner of part "Mini ISU Enclosure-3"); Depending on your sheet metal thickness, features may deform due to the metal stretching/contracting so your hole could get "pulled" towards the bend. Looks like you're .So I managed to get it to bend by adding a very small horizontal line to the curve of the gutter so that it could select a 'fixed face'. But for some reason, after the fold action the two sides of the shape get cut off and I can't figure out why.

Bends in the sheet metal module must be sections of a cylinder. Not true, you can achieve more complex bends using the lofted bend tool. However, you cannot create a compound bended surface, i.e. one that curves in 2 directions at once. See more at: http://www.goengineer.com or http://www.goengineer.com/products/solidworks/ or http://www.goengineer.com/govideochannel/Learn about a few featur.

Kinda but not really. Base flange/tab lets you do native sheet metal parts with no flat sections. Standard models without flat sections can be converted to sheet metal using "insert bends" with a straight edge as the fixed entity. This doesn't work though if the profile is made using splines. The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hi All, i am doing some sheet metal work, and i need to flare the end of some pieces so that the others will fit inside them. basically, lets say i have a 12" x 6" 16 Ga box that i want to match up with another 12" x 6" box.

I do this quite often. When importing into SW you should check that it's come in as a solid Imported body rather than a surface import. If a surface, right click on the feature and do a diagnostic fix. Easier to work with a solid. After this I'll use the convert to sheet metal feature. Will need to ensure the geometry has square edges for this.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .Google: sheet metal tutorial solidworks and follow along.. this is the fastest way to learn. IMO Reply reply stuartnorton • A different way would be 'Base,Flange,Tab, the section profile to give you control over the precise shape of the lip bend, then Tab .Hello and welcom to the continuation of our solidworks course! It has been a while, The reason was we waiting till enough to attend the level1 tutorials the .

solidworks sheet metal pdf

Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations.

how to do sheet metal in solidworks|solidworks sheet metal guide