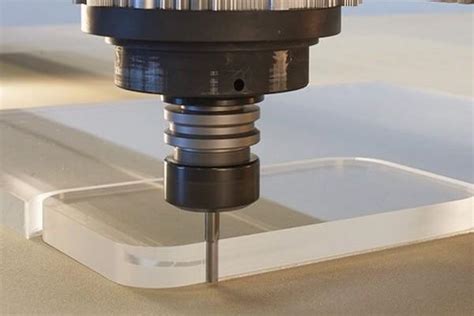

acrylic parts precision machining Acrylic CNC machining offers significant advantages, including producing intricate parts with a polished finish and exceptional accuracy. Whether you need acrylic CNC cutting for signage, display cases, or industrial components, this guide will provide an overview of its benefits, techniques, and best practices. Follow our step-by-step instructions to learn how to install an electric box extender. Easy and affordable DIY.

0 · acrylic machining techniques

1 · acrylic machining process

2 · acrylic machining

3 · acrylic cutting machine

4 · acrylic cnc process

5 · acrylic cnc milling machine

6 · acrylic cnc machining guide

7 · acrylic cnc machining

Discover what custom metal fabrication entails, its benefits, processes, and how it can be tailored to meet your specific project needs. Learn more in this comprehensive guide.

Explore the precision world of Acrylic CNC Machining: Learn techniques, tool selection, applications, and quality assurance for acrylic parts. Discover the edge in cycling with our guide on CNC Machined Bike Parts.

Explore the precision world of Acrylic CNC Machining: Learn techniques, tool selection, applications, and quality assurance for acrylic parts. Discover the edge in cycling with our guide on CNC Machined Bike Parts. CNC machining of acrylic achieves higher accuracy, producing high-precision acrylic components with tight tolerances of +/- 0.01mm, thereby facilitating the machining of complex parts and shortening the production cycle.

CNC machining offers higher precision along with a shorter cycle time, allowing for the production of acrylic parts with high accuracy. Parts with an accuracy of approximately 0.001″ to 0.005″ can be achieved by a typical CNC router that enables the exact machining of intricate acrylic products.

Acrylic CNC machining offers significant advantages, including producing intricate parts with a polished finish and exceptional accuracy. Whether you need acrylic CNC cutting for signage, display cases, or industrial components, this guide will provide an overview of its benefits, techniques, and best practices. CNC machining enables the production of acrylic parts with great accuracy, providing increased precision and faster cycle times. Besides, a standard CNC machine can achieve parts with an accuracy of about 0.001 to 0.005 inches, allowing for the precise machining of intricate acrylic products.CNC machining offers precision and repeatability, allowing for intricate shapes and details that traditional methods cannot achieve. Rapid prototyping with acrylic allows for low-cost functional prototypes, enabling designers to validate their designs before mass production. This online article from Sybridge Technologies provides a comprehensive overview of CNC machining for acrylic parts, emphasizing the versatility and precision of the technique. It discusses various angles and approaches to cutting, which are crucial for achieving high precision and maintaining the material’s quality.

Precision: CNC technology ensures highly accurate and precise cuts, finishes, and shapes on acrylic parts. Versatility: CNC machines can create various shapes and sizes, including complex geometries and delicate designs. Thanks to its precise manufacturing methods, CNC machining can cut acrylic with just the right amount of force to avoid irreversible damage, quickly and effectively producing acrylic components with accurate shapes and sizes.

Let’s learn how to properly machine acrylic sheets using a CNC router and other pieces of machinery. You will also discover how to avoid acrylic melting and how to choose the right cutter. 1. Why Use CNC Machining to Cut Acrylic?

acrylic machining techniques

acrylic machining process

metal donation box australia

Explore the precision world of Acrylic CNC Machining: Learn techniques, tool selection, applications, and quality assurance for acrylic parts. Discover the edge in cycling with our guide on CNC Machined Bike Parts. CNC machining of acrylic achieves higher accuracy, producing high-precision acrylic components with tight tolerances of +/- 0.01mm, thereby facilitating the machining of complex parts and shortening the production cycle.CNC machining offers higher precision along with a shorter cycle time, allowing for the production of acrylic parts with high accuracy. Parts with an accuracy of approximately 0.001″ to 0.005″ can be achieved by a typical CNC router that enables the exact machining of intricate acrylic products.

Acrylic CNC machining offers significant advantages, including producing intricate parts with a polished finish and exceptional accuracy. Whether you need acrylic CNC cutting for signage, display cases, or industrial components, this guide will provide an overview of its benefits, techniques, and best practices. CNC machining enables the production of acrylic parts with great accuracy, providing increased precision and faster cycle times. Besides, a standard CNC machine can achieve parts with an accuracy of about 0.001 to 0.005 inches, allowing for the precise machining of intricate acrylic products.CNC machining offers precision and repeatability, allowing for intricate shapes and details that traditional methods cannot achieve. Rapid prototyping with acrylic allows for low-cost functional prototypes, enabling designers to validate their designs before mass production.

This online article from Sybridge Technologies provides a comprehensive overview of CNC machining for acrylic parts, emphasizing the versatility and precision of the technique. It discusses various angles and approaches to cutting, which are crucial for achieving high precision and maintaining the material’s quality. Precision: CNC technology ensures highly accurate and precise cuts, finishes, and shapes on acrylic parts. Versatility: CNC machines can create various shapes and sizes, including complex geometries and delicate designs.

Thanks to its precise manufacturing methods, CNC machining can cut acrylic with just the right amount of force to avoid irreversible damage, quickly and effectively producing acrylic components with accurate shapes and sizes.

metal dog house reviews

acrylic machining

This is the junction box most people use on 11-speed Di2 bikes. Installing it isn't as straightforward as installing the older below-the-stem junctions, but it's not hard - you just need to know what you're doing.

acrylic parts precision machining|acrylic machining