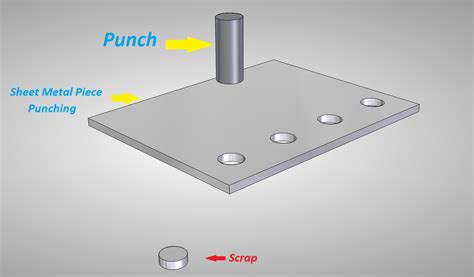

piercing sheet metal process Piercing is a metal fabrication process that create precise holes in sheet metal. The punch penetrates the material to create an opening, but it doesn’t remove any metal. It . On exterior panels I would try to use a preformed patch if it is available and needs to be bigger than a 8” X 8” patch. You can form flat metal too but it takes a little experience and the right technique to get it crowned right.

0 · punching operation in sheet metal

1 · nibbling operation in sheet metal

2 · embossing operation in sheet metal

3 · difference between piercing and punching

4 · difference between piercing and blanking

5 · cutting operation in sheet metal

6 · blanking operation in sheet metal

7 · blanking and piercing diagram

Yes, steel wool comes in varying grades of coarseness. Coarse steel wool is best for heavy-duty work, while fine steel wool is ideal for gentle scrubbing to avoid scratches.

Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and .There are various types of blanking and piercing: lancing, perforating, notching, nibbling, shaving, cutoff, and dinking. Lancing is a piercing operation in which the workpiece is sheared and bent with one strike of the die. A key part of this process is that there is not reduction of material, only a modification in its geometry. This operation is used to make ta. Piercing is a metal fabrication process that create precise holes in sheet metal. The punch penetrates the material to create an opening, but it doesn’t remove any metal. It .Piercing is a metal fabrication technique that creates holes in sheet metal. It uses a punch to penetrate the material, forming an opening without removing any metal. The process displaces the material, often creating a slight bulge around .

There are five types of processes that are generally used in press-work sheet-metal forming: (a) open shearing, (b) blanking, (c) piercing, (d) bending, and (e) deep drawing. .To refine the surface of your metal, you'll use sandpaper across a gradient of grits from (relatively) coarse to fine. Most hardware stores carry sheets of wet-dry sandpaper; pick up a sheet each of 400, 600, and 800 grit.You can tape .

What is Piercing? Piercing is a metal fabrication technique that creates holes in sheet metal. It uses a punch to penetrate the material, forming an opening without removing any metal. The process displaces the material, often creating a .Metal Casting Metal Forming Metal Rolling Metal Extrusion Metal Drawing Sheet Metal Powder Processes Metal Piercing Piercing is a metal forging technique that is often performed as an auxiliary process in conjunction with other forging .

how to run romex to electrical box

Hello Friends Today we will discuss about the Punching and Blanking in this topic with detail example.#Punching, #Piercing, #Blacking, #Punching&Blancking, T. The fundamental goal of sheet metal forming procedures is to give the metal sheets particular geometrical modifications while preserving their structural integrity. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here!Metal piercing is the process of cutting designs, shapes and holes into metal components that are used to create jewelry pieces. It is an essential skill. . punches for sheet metal, sheet metal cutters, sandpaper or abrasive strips, a hammer, a bench pin and an anvil or vice. You should also consider purchasing earring converters if needed . In the realm of sheet metal fabrication, where precision and efficiency reign supreme, self-piercing riveting (SPR) emerges as a transformative technology, revolutionizing the way we assemble sheet metal components. Introduction SPR defies conventional joining methods by eliminating the need for pre-punched holes. Instead, a specially designed SPR tool pierces .

Blanking and Piercing Process | Definition | Metal Forming Process | PPT | ENGINEERING STUDY MATERIALSBlanking and piercing are shearing processes in which a. Subject - Manufacturing Processes, MetallurgyChapter - Difference between Blanking, Piercing, Punching, Lancing, Notching Process, Sheet metal WorkingTimecod. 3.1 Shearing: Principle of Operation. Shearing, or open shearing, is a sheet-metal cut-off operation along a straight line between two cutting edges.In shearing, a piece of sheet metal is separated by applying a shearing force that is high enough to exceed the ultimate shear strength of the material; the excessive applied shear stress causes fracture and separation at .Process Home: Sheet Metal: Bending: CNC Fabrication: Laser Cutting: Shearing: Staking: Stamping Blanking Deburring Drawing Forming Gage of Sheet Metals Machining: Piercing: Welding: Resources: Bibliography: . Piercing is the operation of cutting internal features (holes or slots) in stock. Piercing can also be combined with other operations .

The only difference between perforating and piercing is the coverings in every hole. 8. Slotting. Slotting is a sheet metal process where a slot is put in the metal to do its job. Also known as slitting, the machines used in the process are called slitting machines. . It is a sheet metal process done to the edge of the sheet, whether creating .

This case study is about preparation of process FMEA for the sheet metal part. The operation includes blanking and piercing operation of progressive die. The process FMEA was carried out for blanking and piercing process. The potential failure modes for blanking and piercing process considered from the previous experience. 1.

Even after the development of various non-conventional processes for sheet metal cutting, the shearing process remains the most preferred process in mass production. Sheet metal punching is the process of creating holes in sheet metal using a punch press or a CNC punching machine. The process involves cutting and piercing the sheet metal using dies mounted on presses. Different . Blanking and piercing are manufacturing processes by which certain geometrical shapes are sheared off a sheet metal. If the sheared off part is the one required, the processes referred to as . 8. SHEARING • It is a process of cutting a straight line across a strip, sheet • Metal is placed between upper punch & lower die. • Pressure is applied, plastic deformation takes place. • As the pressure is continued, the .

Chapter 1 Roll Forming in Sheet Metal Forming: Principles and Processes . Suman Deb. Chapter 2 A Systematic Review of the Rotary Piercing Process . Pravin Pawar, Amaresh Kumar, and Raj Ballav. Chapter 3 Finite Element Analysis of the Metal Spinning Process . N. Balaji and D. Nagarajan. Chapter 4 High-Energy Rate Forming . Jagadeesha T. Chapter 5 The Formability .

A sheet metal stamping process is a metalworking process carried out at room temperature wherein parts are both cut and shaped from a parent metal strip or. . the next step would be a piercing process. If the part is a shallow dish with a hole in the bottom, the next two steps would be forming and piercing. . Analysis and Optimization of Sheet Metal Forming Processes comprehensively covers sheet metal forming, from choosing materials, tools and the forming method to optimising the entire process through finite element analysis and computer-aided engineering.. Beginning with an introduction to sheet metal forming, the book provides a guide to the various . Sheet Metal Embossing Process Animation in SolidworksEmbossing:It is a Metal Forming Process for Producing raised or sunken designs in sheet metal material b.

The best way to understand piercing is to think of it as the opposite of a blanking operation. In other words, unlike blanking, the slug is discarded and the hole is saved. Often called perforating, piercing is a metal cutting operation that produces a round, square, or special-shaped hole in flat sheet metal or a formed part.

SHEET METAL PROCESS - Download as a PDF or view online for free. Submit Search. . Punching or Piercing: Punching operation is producing the hole on the workpiece by a punch. In punching, the removed metal is called scrap and . So having a basic idea about sheet metal fabrication process is important before we jump into Blanking, Piercing, and punching. Sheet metal fabrication is a metalworking process to cut and form .

Actually, sheet metal piercing is the opposite of sheet metal blanking. In fact, you can perform sheet metal blanking and piercing simultaneously. . Automotive Industry – automotive sheet metal stamping process, from brackets, vehicle parts, engine components, steering assembly parts, piston assembly switches, etc. There are many stamped . The blanking process involves cutting out desired shapes from a larger sheet of metal. The cut-out piece is known as a “blank” and is used as the primary product, while the remaining sheet material is discarded. Blanking is widely used due to its ability to produce parts quickly and in large volumes.The document discusses the design and analysis of piercing tools. It describes how piercing tools are used to manufacture sheet metal parts in large quantities by cutting out the desired shapes. The methodology used for the project is outlined, including defining the problem statement, scope, data collection, analysis, and development of a solution. Details are provided on modeling and .

punching operation in sheet metal

If the "device yoke" is in contact with the metal box, then you probably do not need to run a ground wire to the device's ground screw. But if in doubt, running the extra conductor will not do any harm.

piercing sheet metal process|blanking operation in sheet metal