sheet metal spinning parts If you need to custom a sheet metal parts for your product, KDMfab is your first choice. Send us your detailed requirement and get an instant quote now.

I'm setup for both and used both with different guns (M15 and M25 setups on a MM210 welder). I've pretty much settled in with Lincoln's L56 .030" wire for everything, including sheetmetal. Like Hankj says, its more technique than wire size when it comes to sheetmetal.

0 · what is metal spinning process

1 · tool rest for metal spinning

2 · stainless steel metal spinning

3 · metal spinning vs deep drawing

4 · metal spinning process step by

5 · metal craft spinning and stamping

6 · manual metal spinning

7 · industrial metal spinning

We stock 1- through 24-inch well casing in all commonly used wall thicknesses. As a distributor and fabricator of casing pipe, we can provide the diameter, wall thickness, and length configurations you require, including threaded pipe through 12 ¾-inch O.D.

Parts can be spun with or without a mandrel in conventional spinning, and performed on a manual or a CNC metal spinning lathes. Two . Metal Spinning Tools & Machines. Metal spinning lathes fall into three general categories, each particularly suited for certain applications depending upon the material and dimensions of the workpieces. Manual .By utilizing rotational force and specialized tooling, spin forming enables the shaping of sheet metal into complex, seamless, and dimensionally accurate components. This article delves into the world of spin forming, exploring its .Shear spinning is a metal spinning variation that produces the desired component in a single pass. It is used to create conical or cylindrical pieces with a specific material thickness. Edge .

The metal spinning process is a technique for shaping sheet metal into hollow, rotationally symmetrical parts. It’s a versatile and cost-effective method for creating a wide range of products, from simple cones to complex .

If you need to custom a sheet metal parts for your product, KDMfab is your first choice. Send us your detailed requirement and get an instant quote now. Metal spinning, also known as spin forming or spinning, is a metalworking process that forms a sheet or tube of metal into an axially symmetric part. This process involves rotating a metal disc or tube at high .All of these parts were produced with metal spinning or shear forming, with the workpiece being formed over a mandrel. Besides multipass spinning and shear forming is another, less common metal spinning iteration called necking-in or .

We are capable to make sheet metal spinning parts with a variety of materials, sizes, and shapes according to your drawing or sample. High Quality. Our extensive experience allows us to create good quality CNC metal spinning .

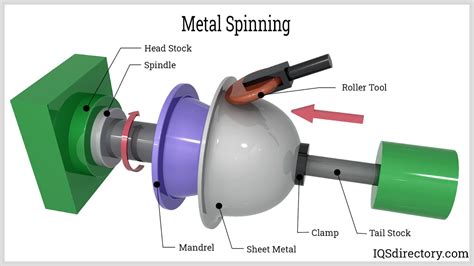

Sheet metal spinning, also known as metal spinning or spin forming, involves rotating a metal disc, known as a blank, while applying pressure to reshape it against a mandrel. This process leverages the principles of centrifugal force and material ductility to form seamless, symmetrical, and highly complex components with exceptional precision .Metal spinning is a method of forming rotationally symmetrical sheet metal parts. In spinning, the sheet metal discs are formed into rotationally symmetrical hollow shapes. The blank is clamped between the shaped spinning mandrel and the tailstock of .The Shapes Achieved Of Metal Spinning Parts. Simple shapes are easy to make in less time. But for complex shapes, it requires more time because it increases steps as per the block shape. . we offering 5 and 3 axis,Laser Cutter,3D Printer,Sheet Metal Machine,Casting Machie,EDM,Injection Molding Machine,Forging Machine,Stamping Machine . Here are the key parts of a metal spinning machine: Headstock: This is the part of the machine that houses the electric motor and drive system. It is responsible for rotating the mandrel at high speeds. . The mechanics of sheet metal spinning involve a combination of controlled force, material plasticity, and manipulation on a rotating form .

That makes custom metal spinning a very cost-effective option for rounded metal parts and products in industries across the board. At Metal Craft Spinning & Stamping, our hand and CNC lathe operations now serve industries including: Simple setup and quick changeover add up to short lead times for new parts; Design changes with minimum expenseMetal spinning is the process of forming three-dimensional symmetrical parts from flat circles of metal. Metal spinning provides an economical alternative to stamping, casting, and many other metal-forming processes. It is an excellent means of quickly prototyping round hollow metal forms (primarily the realm of expensive sheet metal stamping .Metal spinning produces seamless parts that are durable enough to withstand high internal pressures and external forces. The seams are weak spots in finished parts; they reduce strength and integrity. . Precision sheet metal fabrication is a common manufacturing process where the structure of a metal workpiece is cut, bent, and assembled by .Metal screw spinning is slower compared to methods like casting and stamping. Consistency is not assured when working with metal precision spinning method. Metal sheet spinning has a limitation when it comes to shapes, it can work with axially symmetric parts.

Flow forming and metal spinning today produces parts for the aerospace, defense, oil and gas, nuclear, chemical, decorative components, lighting, musical and medical industries, among others. . The large majority of spun parts can be formed by starting with a blank disk trimmed from standard commercial sheet metal. When starting with a disk .

what is metal spinning process

tool rest for metal spinning

Helander Metal Spinning Company has the capability to spin parts as large as 60” in height and 100” in diameter, in a variety of material thicknesses. The ability to form high-quality, thick components, and large diameters with uniformity at any quantity makes metal spinning an appealing and versatile production method.

Wenzel Metal Spinning is the leading custom manufacturer of spun metal parts for the air movement industry. Wenzel Metal Spinning has been forming the integral components that keep the air, and the industry moving since 1982.

TECH AND BUSINESS SUPPORT. Tech support - ODM support, tmetal engineers could provide ODM suggestions from cost and manufacturing tech side - 3D scanning and 3D model building - 100% CNC custom manufacturing for logo, pattern and other special features - One stop solution for all mechanical parts from rapid prototype , mold making, to finish parts assembly

Limitations: Metal spinning is only suitable for producing rotationally symmetrical parts, with hemispherical thin shell metal parts being the most ideal shape. Size Constraints: The internal diameter of parts formed through metal spinning should be kept within 2.5m. Spinning Process. Step 1: Fix the cut circular metal plate on the machine mandrel

The commonly used metal spinning methods include Inner Core Molding Spinning,Segmented Combination Core Molding Spinning,Hollow Support Tubes or Trays or Rods Spinning,Roller Molding Spinning Core-less Spinning and more . Sheet Metal Parts (41) Box (5) Bracket (5) Cabinet (6) Chassis (12) Enclosure (10) Frame (1) Panel (2) Support (1) Spare .Tiandubang, a leading Metal Spinning manufacturer and supplier in China, boasts a state-of-the-art factory producing high-quality Metal Spinning. With its advanced technology, Tiandubang offers the latest selling items, coupled with competitive quotations, to satisfy global customers. Axial Sheet Metal Spinning with CNC Forming Machine. Tooling plays a critical role in metal spinning, directly impacting the quality, precision, and efficiency of the final product. . High Initial Setup Costs for Complex Parts While metal spinning is cost-effective for small to medium production runs, the initial setup can be expensive for .Introducing ourselves as a best in class service provider for metal Spinning & Deep Drawing Combined with Welding Technology. SHEKINA METAL WORKS is a ISO 9001:2015 certified company. We are a major supplier of Metal Spinning Products and refining services to Automobiles, Textiles, Engineering and Home Appliance industries.

Welcome to Jiangsu TongDe international trade Co.Ltd.TONDE has steadily grown as a full supplier in METAL PRODUCTS offering the better value and service to our customers.our capbilities include Cnc Machining,sheet metral fabication.stamping deep drawing. Metal spinning.aluminum die casting,aluminum extrusion.welding.assembly and packaging.AS one .Meaning of Spinning: Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell. The sheet metal parts that have circular cross-section can be made by this process. Generally, the shapes produced by spinning can also be .

CNC Sheet Metal Spinning Machine: Metal spinning, also known as spin forming or metal turning, is a process used to produce axially symmetric components. . High Initial Setup Costs for Complex Parts While metal spinning is cost-effective for small to medium production runs, the initial setup can be expensive for complex parts. Custom mandrels .G.W.P. AG manufactures small batches of rotationally symmetrical sheet-metal hollow bodies based on drawings by deep drawing or metal spinning. By tension and pressure forming, deep drawing and metal spinning, a range of various cylindrical forms, conical shapes and hemispheres can be manufactured for a wide variety of applications.Full service metal spinning facility providing spun metal products, aluminum heat treating, CNC machining, plate rolling, welding and complete metal finishing operations. A sampling of products includes spun metal dished tank heads, nose cones, concentric reducers, airflow nozzles, flanged covers, cones, tubes and cans.

Spinning sheet metal on the lathe is an excellent means for quickly prototyping round hollow metal forms (primarily the realm of expensive sheet . metal, because it requires a minimum of time and money to produce parts. An average part can be spun in five to ten (5-10) minutes once one is familiar with Sheet Metal Shaping with Metal Spinning Machine: Metal spinning, also known as spin forming or metal turning, is a process used to produce axially components. . High Initial Setup Costs for Complex Parts While metal spinning is cost-effective for small to medium production runs, the initial setup can be expensive for complex parts. Custom . Sheet Metal Forming with CNC Metal Spinning Machine: Metal spinning, also known as spin forming or metal turning, is a process used to produce. . High Initial Setup Costs for Complex Parts While metal spinning is cost-effective for small to medium production runs, the initial setup can be expensive for complex parts. Custom mandrels and .

China Sheet Metal Spinning Parts wholesale - Select 2024 high quality Sheet Metal Spinning Parts products in best price from certified Chinese Machine For Metal manufacturers, Metal Cutting Machine suppliers, wholesalers and factory on Made-in-China.com The problem in Sheet metal spinning is limited to an axisymmetric part. This research aims to design and build a flexible mechanism by a combination of mechanical with the electrical system to achieve the forming of polygon spun parts with a different number of sides without using a specific mandrel.

stainless steel metal spinning

metal spinning vs deep drawing

This metal triiger nox for the L96 is made of metal and therefore has a much longer lifespan. As well as being suitable for most L96 sniper rifles, it is particularly suitable for the MB01, MB04, MB05, MB08 and MB14.

sheet metal spinning parts|metal spinning process step by