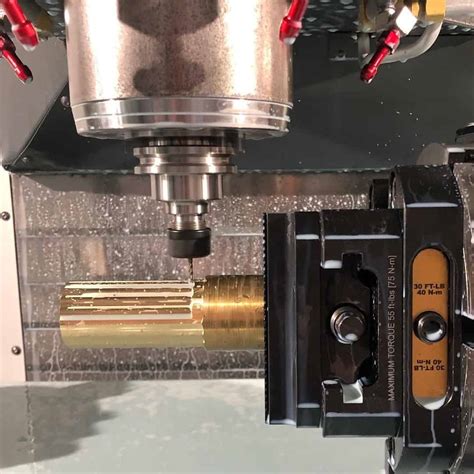

cnc milling copper part CNC milling generates heat during the copper milling process, further enhancing the ductibility of copper. Additional factors which can affect the surface finish while milling copper parts, are tool selection, lubrication, chip load, and the cutting . Shop Storage Bins, Baskets & Containers and other products at Walgreens. Pickup & Same Day Delivery available on most store items.

0 · copper machining tips

1 · copper machining techniques pdf

2 · copper machining practices

3 · copper machining industry

4 · copper machining cutting speed

5 · copper machining

6 · copper grinding machine

7 · copper cnc machining

The average Metal Fabricator salary in South Dakota is $42,874 as of .

sheet metal brake and shear

Advanced CNC techniques, including EDM and precision milling, along with a variety of finishing processes, are essential for producing high-quality copper parts for diverse .We offer two types of copper via our CNC machining service: Copper 101: A 99.99% pure copper alloy with excellent electrical and thermal conductivity, high corrosion resistance, ductility, and impact strength.

CNC milling generates heat during the copper milling process, further enhancing the ductibility of copper. Additional factors which can affect the surface finish while milling copper parts, are tool selection, lubrication, chip load, and the cutting .1. Design Considerations. Design Simplicity: The design should take into account the machining characteristics of copper, avoiding complex geometries and fine features to reduce machining difficulty and cost. Tolerance and Fit: .Nanjing Morong Machinery Technology Co., Ltd.: We're well-known as one of the leading CNC machining parts, bicycle frame building parts, brake parts, dropouts, stem parts enterprises in China. If you're going to buy high quality customized products with competitive price, welcome to get more information from our factory. Regarding high-precision manufacturing, CNC machining is one of the go-to processes, especially using different machines. They are highly efficient and versatile for vast materials, including metal, plastic polymers, and composites. CNC machining copper is a typical process for manufacturing components using this metal. Besides steel and aluminum alloys, .

sheet metal box manufacturers in coimbatore

Check out some of the suitable techniques for copper parts machining below: Milling for Copper Parts. CNC milling is an automated machining process that controls rotary cutting tools’ movement and feed rate. Thus, in CNC milling copper, the tools rotate and move across the surface of the copper materials.CNC Machining Materials for Copper Parts. The excellent thermal and electrical conductivity of 101 and 110 copper alloys makes them a natural choice for bus bars, wire connectors, and other electrical applications. 101 copper (also known as superconducting copper) is more conductive due to its high purity (99.99% copper) but is more cost-effective because 110 is easier to process.CNC machining in Copper Excellent thermal and electrical conductivity Copper offers excellent thermal and electrical conductivity, . CNC machined copper parts begin as raw pieces of metal that are cut down bit by bit to create a desired shape or object. This process is done most accurately with a CNC (Computerized Numerical Control) machine .Customized CNC Machining Parts Supplier, CNC Milling Parts, CNC Turning Parts Manufacturers/ Suppliers - Suzhou Jinquan Jinggong Electronics Co., Ltd. Menu . Aluminum/Aluminium Parts Stainless Steel Parts Brass/Copper/Bronze Parts Titanium Parts Steel Parts Plastic Parts. CNC Machining Service

Select the appropriate machining method: Copper parts can be machined using various methods, including CNC machining, turning, and milling. Selecting the appropriate machining method can help to achieve the desired geometry, accuracy, and surface finish. AN-Prototype provides a complete CNC machining copper service, fully capable of manufacturing complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile, and can be used in applications that require .

It is important to get the correct copper grade for CNC machined parts to achieve desired results while meeting industry standards based on their application. . Copper CNC machining mainly involves milling, turning, and drilling. This is carried out using a computer numerical control (CNC) mill or turning machine, which accurately cuts and .CNC machining of copper utilizes advanced technology to sculpt parts with unmatched precision, leveraging copper's excellent thermal and electrical conductivity. This process, suitable for both prototyping and mass production, employs 3-axis and 5-axis milling to create components with complex geometries and high-quality finishes.Our company excels in the precision processing of copper parts, with a primary focus on turning, milling, and swiss machining. . 0008’’ (0.020 mm) Tighter tolerances are examined on a case by case basis with your technical drawings. Kintech’s CNC machining service can produce CNC parts with tolerance as low as ± 0.0002 in. Without a . Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts.. Copper is written as Cu and listed as atomic number 29 on the periodic table.

A copper part made with CNC machining. Why Copper for CNC Machining? Copper has a vast legacy that spans everything from coins to cookware. Yet, in CNC machining, copper is helpful for its aesthetics and mechanical properties. . CNC Turning Copper on a Lathe. Once the preparation is complete, it's time to delve into the process of CNC turning copper on a lathe. The following step-by-step instructions will guide you through the fundamental stages of CNC turning, from setting up the lathe to producing finished copper parts. 1. Workpiece Setup:

I've been trying to mill some .125" copper sheet with my CNC Sherline mill. I have tried 1/8" and 1/4" end mills, increasing rpm, decrea 581,964 . About twenty years ago a machinist at GE here was killed when trying to drill a 4 inch hole in copper. The drill grabbed, pulled the part from the chuck and killled the operator. My disasters have .

The experimental validation of this process, conducted on a validation part, demonstrated final deviations lower than 0.5% with respect to the desired final part, affirming the feasibility of achieving copper parts with a high degree of dimensional accuracy through the hybridization of ADAM and CNC machining technologies.CNC machining copper parts with excellent mechanical properties, accuracy, and repeatability. 3- and 5-axis CNC milling available. Strengths: Excellent electrical and thermal conductivity, high accuracy & repeatability: Weaknesses: Greater geometry restrictions than 3D printing: Characteristics. Lead Time < 10 days:We offer two types of copper via our CNC machining service: Copper 101: A 99.99% pure copper alloy with excellent electrical and thermal conductivity, high corrosion resistance, ductility, and impact strength. Copper 110 (via Protolabs Network): 99.90% copper alloy used in electrical applications thanks to high thermal and electrical .Sibai provides strictly quality control in the whole process,ensures Copper CNC precision machining parts, from material to finishing, to packing. Click to get cheap copper machined parts now! www . Contact Us. 0086-755-29354715; [email protected]; Capabilities. CNC Machining Auxiliary Metal Processings Sheet Metal .

CNC Machining Parts Supplier, Mold, CNC Milling Parts Manufacturers/ Suppliers - Shenzhen Pans Technology Co., Ltd. Menu Sign In. Join Free For Buyer . China Supplier 5-Axis Stainless Steel Sheet Metal Parts Custom Brass Copper Aluminium Plastic CNC Precision Auto Engine Spare Machining Parts. USZhuohang was founded in 2005 and has over 20 years of experience in CNC precision machining. Call Us: +86(769)83798939. Home; Quality Assurance. Quality System; Testing Machine; Productive Capacity. Production Management . High Precision Wire EDM Machining Parts; Precision CNC turning-milling copper alloy prod. Precision CNC Turning-Milling ..001-1.00 / Piece. 1 Piece (MOQ) Regarding high-precision manufacturing, CNC machining is one of the go-to processes, especially using different machines. They are highly efficient and versatile for vast materials, including metal, plastic polymers, and composites. CNC machining copper is a typical process for manufacturing components using this metal. Besides steel and aluminum alloys, . In the realm of CNC machined parts, achieving the perfect balance of strength, flexibility, and durability often requires meticulous heat treatment processes. One such crucial process is annealing, especially for copper and its various alloys. Annealing not only relieves internal stresses but also enhances the metal’s workability and overall performance.

Precision Copper CNC Machining. Copper, with its remarkable properties, has found its way into diverse industries. From medical devices to aerospace components, precision-machined copper parts are in high demand. Compared to other metals, copper offers its own challenges, so deep manufacturing expertise and experience is required to work with . Factors including the correctness and precision quality when talking about the CNC machining of the copper parts also depend on various encompassed factors as outlined from some of the well-known sources. Computerized Design-Aided (CAD): The use of CAD programs allows to incorporate even the most sophisticated design features and tolerances .

copper machining tips

copper machining techniques pdf

copper machining practices

$255.99

cnc milling copper part|copper machining cutting speed