cnc machining steps There are four basic steps to CNC machining, no matter your CNC machining process. Below is a stepwise procedure on how they generally function: Step 1: Prepare a CAD Model. This involves creating a 2D or 3D . The integral clamp is a metal clip riveted to the box that the NM cable passes under when you shove it through the knockout. The round knockouts in the middle of the box sides require the separate clamp.

0 · how to start cnc machine

1 · how to do cnc machining

2 · cnc machining process steps

3 · cnc machining process

4 · cnc machining instructions

5 · cnc machine setup

6 · cnc machine installation steps

7 · cnc cutting machine setup

$120.00

In this comprehensive guide, we will walk you through the step-by-step process of CNC machining, exploring each stage in detail. Introduction to CNC Machining:\ Before diving into .

how to install junction box in plaster wall

Step-by-Step CNC Machining Process. 1. Designing the CAD Model. The first step in CNC machining is creating a detailed CAD (Computer-Aided Design) model of the part to be manufactured. This digital model serves as the . There are four basic steps to CNC machining, no matter your CNC machining process. Below is a stepwise procedure on how they generally function: Step 1: Prepare a CAD Model. This involves creating a 2D or 3D .Step 1: Choose Your Workspace. Find a suitable location for your CNC machine. Ensure you have enough space to move around comfortably and access power outlets. Consider .

how to start cnc machine

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .The automated nature of CNC machining makes it possible to create simple, high-precision parts with high accuracy; and to fabricate unique, medium-scale production series cost-effectively. What are the main steps of CNC machining?

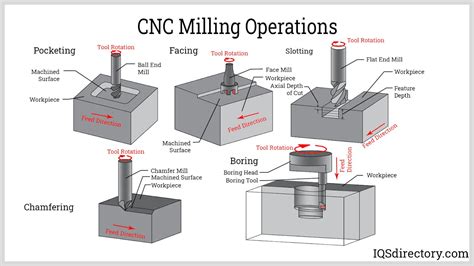

In this section, we walk you through the 3 simple steps needed to manufacture custom parts with CNC machining. Step 1: Export your design to a CNC-compatible CAD file format The file formats predominantly used in CNC . The overall CNC machining process consists of four main steps, as listed below: 1. Designing the CAD Model. A CAD (Computer Aided Design) 3D model is developed by an engineer or designer. This part is designed .Getting Started: Machine Setup. Setting up your first CNC machine might seem daunting, but breaking it down into manageable steps can simplify the process. Step 1: Choose Your Workspace. Find a suitable location for your CNC machine. Ensure you have enough space to move around comfortably and access power outlets.Milling is a subtractive process for fabrication in which you begin with a solid block of your stock material and cut away at it to reveal your final desired object.CNC stands for computerized numerical controlled, and together CNC milling .

how to do cnc machining

cnc machining process steps

Establishing the work coordinate system (WCS) is a fundamental step in CNC machining. It defines the origin point from which all measurements are taken. Establish the Work Coordinate System (WCS): Set the zero points .

Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control. Start and home a CNC machine. Load tools into tool carousel. Set Tool Length Offsets. Set Part Offsets. Load a CNC program into the machine control. Dry run; Safely run a new .

CNC machining is at the heart of this transformation, shaping everything from intricate details to robust components. Explore this guide to grasp CNC machining’s essentials and its impact on manufacturing. . CAD or computer-aided design is the first step in the CNC manufacturing process. A computer-aided design package will allow the user .

The CNC Machinist's Role in Manufacturing In this section, we explore the role of a CNC machinist in a CNC Machining manufacturing plant.CNC machinists are responsible for operating computer numeric controlled (CNC) milling machines and lathes. They work with a number of different types of materials, such as metals and. Lead times in CNC machining represent the total time from when an order is placed until the final product is ready for shipment. Understanding these lead. Get Quote. . Detailed Steps and Parameters. Cutting Speed and Feed Rate: To calculate the cutting speed, use the formula: Cutting Speed = (3.1416 x Diameter of Cutting Tool x RPM) / 12; CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. This is until the material forms the input designed part. Step 3: Machining the Fastener. Now that the design is finalized, and the CNC machine is set up and calibrated, the manufacturing process can begin. In this step, the CNC machine translates the CAD model into a physical object. The raw material is loaded into the CNC machine, and the machine’s cutting tools get to work, carving the fastener .

One of the most important steps in effectively operating a CNC machine is securely fixing your workpiece in place. Take the time to properly align and tighten the clamps, ensuring that the workpiece is held firmly to avoid any vibrations or movement during machining. CNC machining is the process of removing material based on a set of computer-generated instructions. Learn more about this technology and how it can be used in manufacturing. . The overall CNC machining process consists of four main steps, as listed below: 1. Designing the CAD Model.

Three Steps to Reduce CNC Machining Waste . Sustainability is a key concern in CNC machining, with manufacturers grappling to minimize material waste and maximize machine efficiency while maintaining profitability. Going circular. Material waste remains pervasive in machining but, recycling rates for metals are far lower than their potential .STEP for CNC Machining. The STEP-NC AP238 standard is the result of an international effort, begun in the late 1990s, to replace the RS274D (ISO 6983) M and G code standard with a modern associative language that connects the CAD design data used to determine the machining requirements for an operation with the CAM process data that solves those .

Key Steps in CNC Milling: Design Creation: Using CAD software to design the part. Programming: Converting the design into G-code, the language CNC machines understand. Setup: Preparing the machine and securing the workpiece. Machining: The CNC machine mills the part according to the programmed instructions.In this comprehensive guide, we will walk you through the step-by-step process of leveling a CNC machine, sharing valuable tips and techniques along the way. Whether you are a beginner or an experienced CNC machine operator, mastering the art of leveling will undoubtedly contribute to your success in the field. So, let's get started!Steps to Become a CNC Machinist. CNC machinist job functions are highly technical and precise, so intensive preparation and training are required to master the craft. Budding machinists can use vocational or academic paths to meet .

By following these steps, you can get the answer to thee most popular question: “is CNC machinist a good career?” and start your journey towards becoming a CNC machinist. Full training and certification as a CNC machinist usually require four to five years of education and hands-on experience. But don’t let the time investment deter you.

cnc machining process

The frame serves as the backbone of a CNC machine. This step involves constructing the frame and ensuring it is sturdy and stable. Follow the manufacturer's instructions to assemble the frame accurately, paying close attention to the alignment of the various frame components. Use appropriate tools and techniques to achieve precise and accurate . What is stepover: Stepover is the distance your CNC machine moves your bit after each pass in the XY plane, measured as a percentage of the tool diameter.; How stepover affects surface finish: Smaller stepovers result in smoother surfaces and more details, but also longer machining time.Larger stepovers result in rougher surfaces and less details, but also faster . Introduction to 5-axis CNC machining. When people talk about multi-axis CNC machining or multiple machining, 5-axis CNC machining is always mentioned in the advanced manufacturing methods. Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is .Breaking down the precision CNC machining process into these steps can help you appreciate the level of precision and expertise involved in creating high-quality parts and components. JW Machine is an ISO 9001/AS 9100 certified machine shop providing a range of precision CNC machining services such as small part machining, .

CNC Machining . CNC swiss threading in steps. Thread starter AHC . . CNC swiss threading in steps. Thread starter AHC; Start date Jan 30, 2016; Replies 5 Views 5,098 A. AHC Aluminum. Joined Aug 5, 2011 Location NJ USA. Jan 30, 2016 #1 Just wondering if anyone has any tips for threading custom buttress threads on an angle, nearly 1.5 inches .

When machining a part, there are several important steps to follow. This methodology optimizes production, ensures that the parts are machined correctly and reduces the number of errors. The method is used by many industrial machining companies. Our machining company presents the main steps of the machining process in this article. 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In . Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and preparation, it can be a straightforward process. CNC milling machines are used in a variety of industries, from automotive to aerospace, and are prized for their accuracy and efficiency. In this article, we will provide a step-by-step guide [.]

In this comprehensive guide, we will explore the step-by-step process of creating a CNC router machine from scratch. Get ready to embark on an exciting journey of craftsmanship and innovation! 1. Understanding CNC Router Machine Basics: What is a CNC router machine? Components of a CNC router machine . Different types of CNC router machines Step 3: Setting Up the CNC Machine. Fixtures and Tooling: Before machining begins, the machinist installs fixtures to hold the workpiece securely in place. The tooling selected in the previous step is also set up. Machine Calibration: The CNC machine must be calibrated to ensure precision. This involves checking tool offsets and verifying the .

cnc machining instructions

Installing electrical boxes and cables is made easy by following these recommended electrical installation codes. Don't just install your electrical wiring haphazardly, do it by the book of the National Electrical Code .

cnc machining steps|cnc machining instructions