punching sheet metal process Sheet metal punching is a cost-effective and accurate process for creating holes and shapes in sheet metal components. By following a guide, implementing quality control, addressing challenges, and ensuring safety, . $13.99

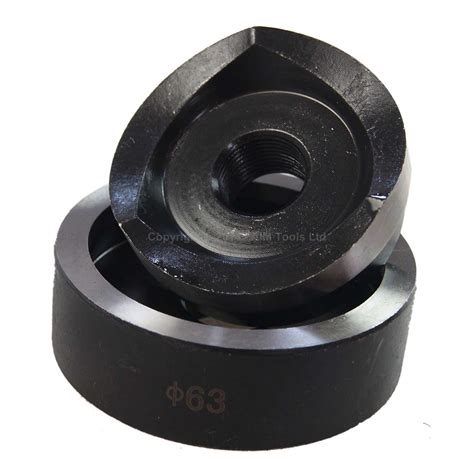

0 · sheet metal punch dies

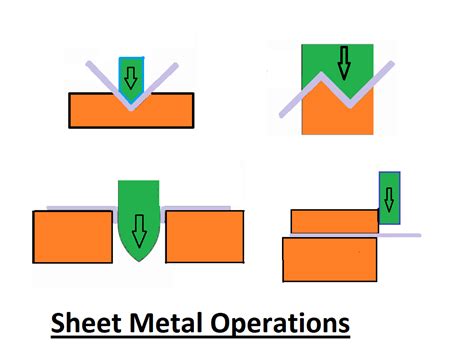

1 · sheet metal operations with diagrams

2 · sheet metal hole punching machine

3 · shearing operation in sheet metal

4 · punching holes in sheet metal

5 · perforating operation in sheet metal

6 · embossing operation in sheet metal

7 · drawing operation in sheet metal

Rather than relying on the government, as a union worker you can instantly address .

Sheet metal processes involve a variety of methods to cut thin metal sheets. Understanding Piercing, Punching, and Blanking What is Piercing? Piercing is a metal fabrication process that create precise holes in sheet . Sheet metal punching is the process of creating holes in sheet metal using a punch press or a CNC punching machine. The process involves cutting and piercing the sheet metal using dies mounted on presses.

Sheet metal punching is a manufacturing process that uses a punch and dies to create holes and other features in sheet metal. The punch is a tool pressed into the sheet metal, while the die supports the sheet metal .

Sheet metal punching is a cost-effective and accurate process for creating holes and shapes in sheet metal components. By following a guide, implementing quality control, addressing challenges, and ensuring safety, . What is Sheet Metal Punching? Sheet metal punching is a manufacturing process used to create holes or shapes in metal sheets or plates with the help of a punch press. In this technique, a punch—a stiff metal rod with a specific shape at one end—strikes the metal sheet placed over a die.

The success of the sheet metal punching process depends largely on the design and quality of the punch and die set. These components come in various shapes and sizes to accommodate different types of punching operations. For example, a punch designed for piercing will have a pointed tip, while a blanking punch will have a larger flat surface. . The sheet metal blanking process involves several critical steps that must be carefully executed to ensure high-quality results. The common steps include material selection, designing the punch and die, setting up the .

sheet metal punch dies

Sheet Metal Punching Process Pre-punching preparations Material Selection. Selecting the suitable material is essential before we begin punching. In Part I, we explained that different metals have properties such as hardness and flexibility, which directly affect the quality of the final product. We consult our clients at Shengen to ensure that .

Blanking is a process that precisely cuts out a product from sheet metal. A punch and die are used to remove the material through massive shearing forces. The desired shape, which is punched out, is used for specific applications while the excess is treated as scrap material. . Punching is a widely used process in virtually all industries . The punch is a tool pressed into the sheet metal, while the die supports the sheet metal during the punching process. The hole or feature is created by the punch pressing into the sheet metal and cutting through it. Sheet metal punching is a very versatile process that can be used to create a wide variety of holes and features in sheet metal .

Sheet metal punching: Notching operation: Surface of operation : It only takes place within the piece of a sheet metal perimeter to remove the unwanted materials. . In the process of making metal furniture, the sheet metal notching process is used to .

Sheet metal punching process. The sheet metal punching machines use metal punches and die. Punches pass through the sheet metal, while the dies are located on the opposite side of the metal piece. These dies support the metal and ensure that the metal does not break, further, they also help punches in making accurate holes. This process allows .

sheet metal operations with diagrams

Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the required hole shape. And these determine the ease or .

Sheet metal punching is a crucial process in precision sheet metal fabrication, playing a vital role in creating a wide array of finished and semi-finished products. This technique involves using a punch tool to impress a form on a metal surface through pressure or percussion. Atlas Manufacturing, a pioneer in the sheet metal fabrication .The punched out offcuts are gathered in the punch container. Punching metal works in the exact same way: the sheet lies between the punch and the die. The punch moves down and dips into the die. The edges of the punch and die move past each other in parallel, cutting the sheet. This is why punching belongs to the shear cutting process group.

Punching is a prominent process in sheet metal fabrication that involves the use of a punch and die to create holes, slots, or other geometric features in sheet metal. This versatile technique is widely employed in the production of sheet metal components across diverse industries, including automotive, electronics, and construction.Punching sheet metal takes an equal amount of precision and skill, especially when delivering critical sheet metal parts used in the information & communications, medical, aerospace & defense, and energy industries. . Plus, CNC enables a faster and more accurate process while producing complex shapes and patterns. .

Looking for skilled sheet metal punching professionals? PMF has got you covered! Learn the process of metal punching and start your project with us today. 919-231-8648 [email protected] Request a Quote. . The sheet metal punching process also provides excellent precision and accuracy, ensuring each component is cut to the specified dimensions. . Process of Sheet Metal Punching. The process entails placing a flat metal sheet on a die with a hole that matches the desired feature’s shape and size. A punch rapidly descends and penetrates the material, creating the .

The success of a punching part begins in the design. TRUMPF offers you a comprehensive knowledge platform for this first process step with the PunchGuide as well as effective checking and optimisation of your sheet metal components with Optimate.In addition, we provide support for you with a comprehensive range of training courses and workshops covering all aspects of . Sheet metal nibbling process. Nibbling is a sheet metal cutting technique that involves removing material incrementally. Nibbling allows for intricate patterns, curves, and shapes by creating overlapping holes or . Subject - Manufacturing Processes, MetallurgyChapter - Difference between Blanking, Piercing, Punching, Lancing, Notching Process, Sheet metal WorkingTimecod. For additional information, visit: http://bit.ly/QYucWpand don't forget to subscribe to our channel here http://www.youtube.com/user/MechanicsTips-----.

sheet metal hole punching machine

Sheet Metal Punching Mechanism. This process is also known as Sheet Metal Hole Punching because it makes different shapes of holes on the sheet. A punch tool exerts force in sheet metal so the intended portion is punched out and results in precise and clean holes or cutouts similar to Puch’s geometry.Sheet metal punching offers quite a few important benefits for metal fabrication, some of these are: Versatility: Sheet metal punching can be used to create a wide range of shapes and sizes, from simple round holes to complex cutouts and embossing enabled by custom tooling.. Tight tolerances: CNC punch presses offer precise control over the punching process, resulting in .

Sheet metal punching is a crucial process in the automotive industry, used for producing various components such as body panels, chassis, and structural parts. It involves the use of a punch and die to create holes or cutouts in sheet metal, allowing manufacturers to produce complex shapes and designs with precision and efficiency. . Now, let’s overview the sheet metal punching process and the factors that can influence its success. 1. Sheet Metal Punching Process Overview. The sheet metal punching process can be broken down into several steps. Firstly, the sheet metal is placed on a work surface or table, with the punch and die aligned above and below the material . Sheet metal punching is a versatile and efficient process with a wide range of applications across various industries. Its advantages in terms of precision, production rate, cost-effectiveness, and design flexibility make it a preferred choice for many manufacturers. This paper presents the process to construct a digital twin for a sheet metal punching machine to support the interactive design of optimal NC machining programs.

Laser punching harnesses the power of concentrated laser beams to vaporize material and create precise holes or shapes. This non-contact process eliminates the need for physical punches and dies, resulting in clean and burr-free edges. Laser punching boasts versatility, handling a wide range of metal sheet thicknesses and intricate geometries. 2. Introduction: Punching and blanking processes are sheet metal forming processes. In these two processes a finite volume of metal from a sheet is removed by using die and punch. The shape and size of the portion removed depends on the geometry of die and punch. Also the operation cost and time depends on die and punch design.

mini metal box cutter

mini sugar freepeppermints made in canada in metal box

Vintage 1930's Biscuit Box | Uneeda Bakers Complete Box | Glass & Metal Lid with Wood Frame | Knob on Front | National Biscuit Company

punching sheet metal process|shearing operation in sheet metal