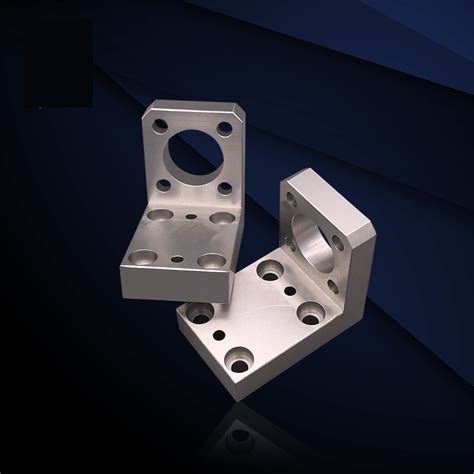

anodised aluminium cnc parts Finishing Options for CNC Machined Aluminum Parts. Anodizing is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Three types of aluminum anodizing are available from Protolabs: Type I-Chromic Acid: Provides a whisper-thin but still durable coating. Thankfully, there is a solution, and that is to build a shop house, or “shouse,” also sometimes called a shop home, or “shome.” What is a Shouse? A “shouse” is exactly what the name implies.

0 · aluminum cnc service

1 · aluminum cnc parts

2 · aluminum cnc machining

3 · aluminum anodizing parts

Angela joined the Western Washington Sheet Metal JATC in 2017 after transferring from the SM JATC in Las Vegas, where she had been employed since 2008. Her introduction to the sheet metal industry came through a friend who worked at the JATC and recommended it as a promising career path.

Finishing Options for CNC Machined Aluminum Parts. Anodizing is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Three types of aluminum .At CNCRUSH, we offer high-quality anodizing services for parts that meet stringent technical and visual standards. Our anodizing capabilities include both decorative and technical treatments .Anodising Options for CNC Machined Aluminium Parts. Anodising is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Two types of aluminium .Finishing Options for CNC Machined Aluminum Parts. Anodizing is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Three types of aluminum anodizing are available from Protolabs: Type I-Chromic Acid: Provides a whisper-thin but still durable coating.

At CNCRUSH, we offer high-quality anodizing services for parts that meet stringent technical and visual standards. Our anodizing capabilities include both decorative and technical treatments to enhance the durability and appearance of your aluminum components.Anodising Options for CNC Machined Aluminium Parts. Anodising is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Two types of aluminium anodising are available from Protolabs: Type II-Sulfuric Acid: Provides an exceedingly durable finish.

Unlock the secrets of anodized aluminum for durable, corrosion-resistant parts. Ideal for manufacturers seeking OEM solutions. Click for a full process guide!Anodizing grows the natural oxide layer on aluminum parts for wear and corrosion protection. Get cnc machined parts anodized with Fictiv.At ProleanTech, we have multi-axis (3, 4, 5-axis) CNC milling and machining centers to craft complex parts with intricate features from aluminum workpieces. Our diverse machining capabilities, like milling, turning, drilling, and threading, can accommodate different designs, from automotive and aerospace to electronics components.Anodizing, a tried-and-true method of enhancing aluminum, has played a pivotal role in various engineering applications. That’s especially the case for CNC machining and sheet metal fabrication projects. This article delves into anodizing, showing you the process, the main benefits, and when to opt for this finishing method.

eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. Anodizing aluminum is an excellent choice when requiring professional aesthetic appearance and great mechanical properties of CNC parts. As a popular post-processing method, anodizing can not only be applied on aluminum, but also suitable for many other metals. Discover the benefits and process of anodizing aluminum for CNC machining, enhancing durability and corrosion resistance in precision parts.Finishing Options for CNC Machined Aluminum Parts. Anodizing is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Three types of aluminum anodizing are available from Protolabs: Type I-Chromic Acid: Provides a whisper-thin but still durable coating.

At CNCRUSH, we offer high-quality anodizing services for parts that meet stringent technical and visual standards. Our anodizing capabilities include both decorative and technical treatments to enhance the durability and appearance of your aluminum components.

aluminum cnc service

aluminum cnc parts

Anodising Options for CNC Machined Aluminium Parts. Anodising is one of the most common finishing options, offering strong corrosion protection and enhancing the overall appearance of metal parts. Two types of aluminium anodising are available from Protolabs: Type II-Sulfuric Acid: Provides an exceedingly durable finish. Unlock the secrets of anodized aluminum for durable, corrosion-resistant parts. Ideal for manufacturers seeking OEM solutions. Click for a full process guide!

Anodizing grows the natural oxide layer on aluminum parts for wear and corrosion protection. Get cnc machined parts anodized with Fictiv.

At ProleanTech, we have multi-axis (3, 4, 5-axis) CNC milling and machining centers to craft complex parts with intricate features from aluminum workpieces. Our diverse machining capabilities, like milling, turning, drilling, and threading, can accommodate different designs, from automotive and aerospace to electronics components.Anodizing, a tried-and-true method of enhancing aluminum, has played a pivotal role in various engineering applications. That’s especially the case for CNC machining and sheet metal fabrication projects. This article delves into anodizing, showing you the process, the main benefits, and when to opt for this finishing method.eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA.

Anodizing aluminum is an excellent choice when requiring professional aesthetic appearance and great mechanical properties of CNC parts. As a popular post-processing method, anodizing can not only be applied on aluminum, but also suitable for many other metals.

aluminum cnc machining

x-parts sheet metal

Fabricated metal refers to metal that is cut, bent, and assembled to create usable metal structures, parts, or products. The final fabricated metals are essential components for .

anodised aluminium cnc parts|aluminum cnc parts