cnc machine setting procedure Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly . In summary, a junction box is a crucial component in the proper installation of your Bosch dishwasher. It ensures compliance with electrical codes, provides protection for the electrical connections, and offers easy access for future maintenance or repairs.

0 · starting up dewalt cnc machine

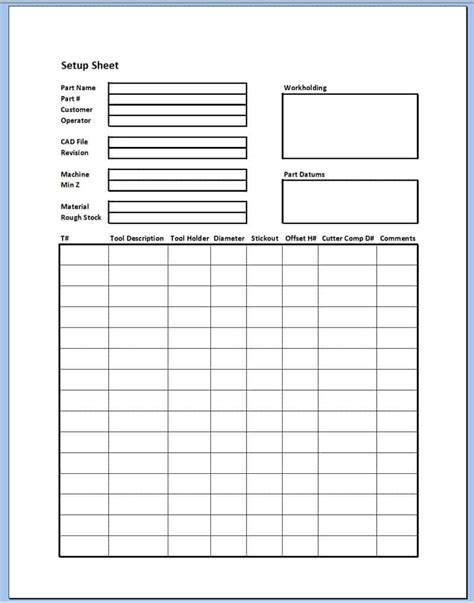

1 · cnc tool set up sheet

2 · cnc mill set up sheet

3 · cnc machines for dummies

4 · cnc machine setup sheet template

5 · cnc machine setup sheet

6 · cnc machine setup checklist

7 · cnc lathe setup sheet

Need some advice on adding a seperate power supply for my welder. Roughly what size wire would I need for a 300 amp welder and what size circuit breaker would I need .

starting up dewalt cnc machine

tamper proof junction box

Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly .In this blog post, we will provide a step-by-step guide on CNC machine setting procedures to help you master this essential skill. From machine preparation to tool selection and calibration, we .In this article, we will provide a detailed guide on how to set up a CNC machine effectively, covering everything from machine calibration to tool selection, workpiece setup, and machine . We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions. .

Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the .

This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup .Before starting the CNC machine, it is essential to ensure that all necessary preparations are carried out. This section will cover the pre-startup checklist, including inspecting the machine, .We will provide you with the necessary tools and explain how to set up your cnc milling machine for optimal performance in daily operation & production. (1) Before the workpiece is processed, .How to Set Up CNC Milling Machine - Although every CNC Milling machine set-up is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine.

Learn the basics of G-code and M-code, which are the standard programming languages used in CNC machining. Understand how to write and edit CNC programs, input the necessary commands and variables, and .

Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly calibrated and ready for use.In this blog post, we will provide a step-by-step guide on CNC machine setting procedures to help you master this essential skill. From machine preparation to tool selection and calibration, we will cover every critical aspect in detail.In this article, we will provide a detailed guide on how to set up a CNC machine effectively, covering everything from machine calibration to tool selection, workpiece setup, and machine optimization.

cnc tool set up sheet

We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions. Whether setting up a home CNC machine or preparing for large-scale production, this guide is your gateway to becoming a skilled CNC machine operator. Understanding CNC .Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the material blank. Tool Calibration: Calibrate tools to ensure correct positioning and alignment. This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine.Before starting the CNC machine, it is essential to ensure that all necessary preparations are carried out. This section will cover the pre-startup checklist, including inspecting the machine, checking power supply and connections, verifying coolant .

We will provide you with the necessary tools and explain how to set up your cnc milling machine for optimal performance in daily operation & production. (1) Before the workpiece is processed, it is necessary to program the machining program first.

How to Set Up CNC Milling Machine - Although every CNC Milling machine set-up is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine. Learn the basics of G-code and M-code, which are the standard programming languages used in CNC machining. Understand how to write and edit CNC programs, input the necessary commands and variables, and troubleshoot common programming errors.

Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly calibrated and ready for use.In this blog post, we will provide a step-by-step guide on CNC machine setting procedures to help you master this essential skill. From machine preparation to tool selection and calibration, we will cover every critical aspect in detail.In this article, we will provide a detailed guide on how to set up a CNC machine effectively, covering everything from machine calibration to tool selection, workpiece setup, and machine optimization. We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions. Whether setting up a home CNC machine or preparing for large-scale production, this guide is your gateway to becoming a skilled CNC machine operator. Understanding CNC .

Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the material blank. Tool Calibration: Calibrate tools to ensure correct positioning and alignment. This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine.

Before starting the CNC machine, it is essential to ensure that all necessary preparations are carried out. This section will cover the pre-startup checklist, including inspecting the machine, checking power supply and connections, verifying coolant .We will provide you with the necessary tools and explain how to set up your cnc milling machine for optimal performance in daily operation & production. (1) Before the workpiece is processed, it is necessary to program the machining program first.How to Set Up CNC Milling Machine - Although every CNC Milling machine set-up is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine.

Protect your designs from condensation, rain, washdown, & oil, all while maintaining your enclosure’s IP rating, even up to IP67 with Bud IP-rated vents.

cnc machine setting procedure|cnc tool set up sheet